Tools for countersinking or chamfering without stopping machining

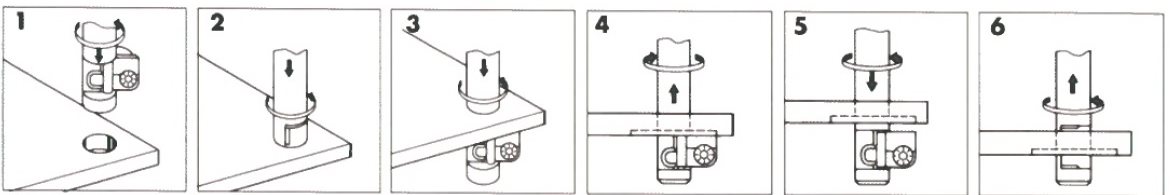

Erix Tool countersinks reduce countersink cycle time by 90%, eliminating the need to stop the program and manually operate the tool.ERIX countersinks are a patented design consisting of a spindle and a tilt-mounted wing. In the first phase of the cycle, the tool rotates counterclockwise, which causes the wing to close in the spindle seat. Then the countersink passes through the prepared hole. After passing through the material, the direction of rotation should be changed to the direction consistent with the movement of the zegrar pointers and the working feed should be started. This will open the wing and bring the blade to the ready position. After countersinking, withdraw the blade in the direction away from the material and change the direction of rotation to counterclockwise again. Now you can withdraw the countersink from the hole, the wing will close automatically when it comes into contact with the material.

Benefits of using Erix countersinks

- Reduction of dredging cycle time by up to 90%

- Eliminate the need to stop the program and manually operate the tool

- Time-saving thanks to the possibility of chamfering face and back chamfers with one tool

- Machining in areas inaccessible to the operator, e.g. closed chambers

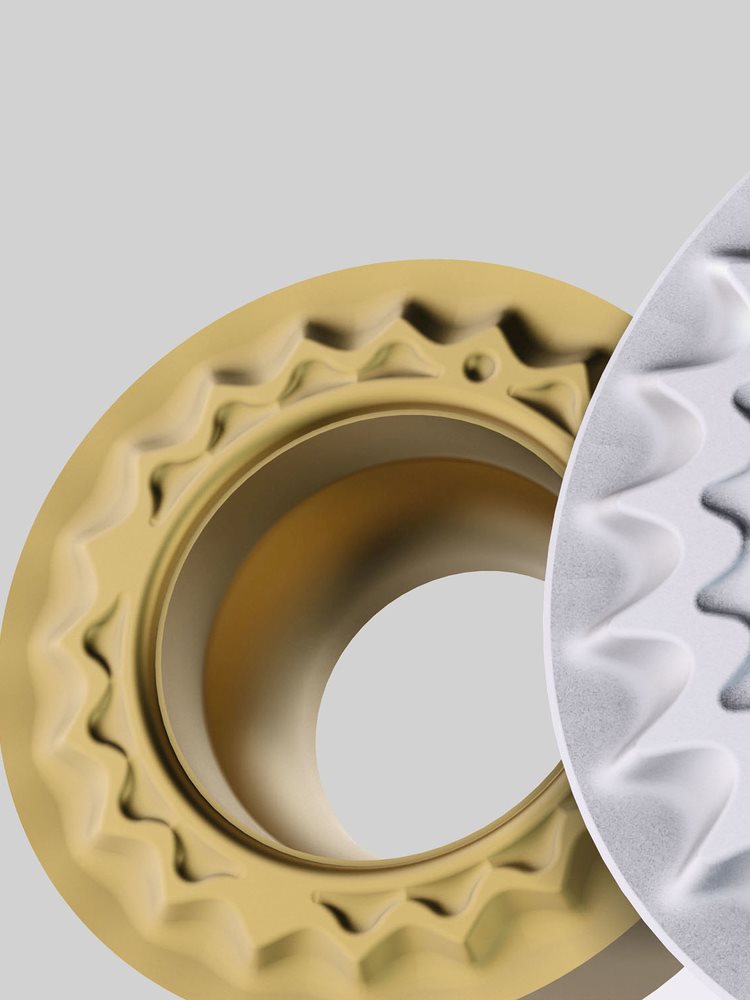

Standard Erix countersink range

- Diameter range from Ø4.5 to Ø69.0 mm

- Tools available with Weldon shank and Morsea taper

- Coolant ducts to the blade

- Indexable inserts can be used in two grades: K20 for cast iron and P40 for steel

Available Operations

- Chamfering 30º, 45º and 60º

- Frontal and posterior countersinking

- 45º Face and Back Chamfer

Ability to machine a wide range of materials from steel, cast iron to aluminum and titanium.

For further information, please contact us.

Inline Content - Gridded Links

Tags: 'contact'

Max links: 1

Download the Erix catalogue here

Related content

WEBINAR - IMPROVE YOUR PERFORMANCE IN HIGH-MIX, LOW-VOLUME MACHINING

PREZENTACJA SN2024.1

Responsible sourcing of minerals and metals at Seco

Leading the discovery of the future – Sustainable machining through data intelligence

Seco Component Guidance provides tailored on-demand tooling recommendations

50 Years of Seco Tools in Poland

Why making an aeroplane pylon is a true collaborative process

Seco Green Fund Achieves Sustainability Goals for Over a Decade

FREZY WĘGLIKOWE SECO JSE510

PREZENTACJA SN2024.1

POZNAJ NASZĄ NAJNOWSZĄ PROMOCJĘ