How to Achieve Precision in Drilling Applications: Solid Drills Strategies and Maintenance

Precision drilling plays a critical role across industries, especially when working with hard-to-machine materials. Explore how to machine tough materials effectively.In today’s advanced manufacturing landscape, precision drilling plays a critical role across industries such as aerospace, medical devices, energy and automotive – all key sectors for Seco. These industries often require machining difficult-to-machine materials (DTMM), including hardened steels, high-temperature alloys like titanium and Inconel, stainless steels and composites.

While these materials offer superior hardness, heat resistance, and durability they also pose significant machining challenges. To drill tough materials effectively, it requires selecting the right drill, optimizing machine capabilities, devising cutting strategies, and maintaining equipment at all times. Only a well-executed all-round approach will ensure improved hole quality, dimensional accuracy and tool longevity while also reducing downtime and scrap rates.

Difficult-to-machine materials are valued for their strength, corrosion resistance and thermal stability but demand specialized drilling techniques.

Difficult-to-machine materials are valued for their strength, corrosion resistance and thermal stability but demand specialized drilling techniques.

“When cutting tools were first designed, it was basically ‘make it as sharp as you can so that it cuts the material.’ But in some of today’s materials, that doesn’t necessarily work,” says Ricky Payling, Global Product Manager, Solid Round Tools at Seco.

Every type of material brings its own unique challenges. Hardened steel above 45 HRC, for example, provides high wear resistance, but can degrade tools quickly.

Titanium alloys suffer from poor thermal conductivity that leads to localized heat buildup, while composites, due to their layered structure, risk delamination and fiber pull-out if they aren’t drilled correctly.

With that in mind, selecting the correct tool is the first essential step in the process.

With that in mind, selecting the correct tool is the first essential step in the process.

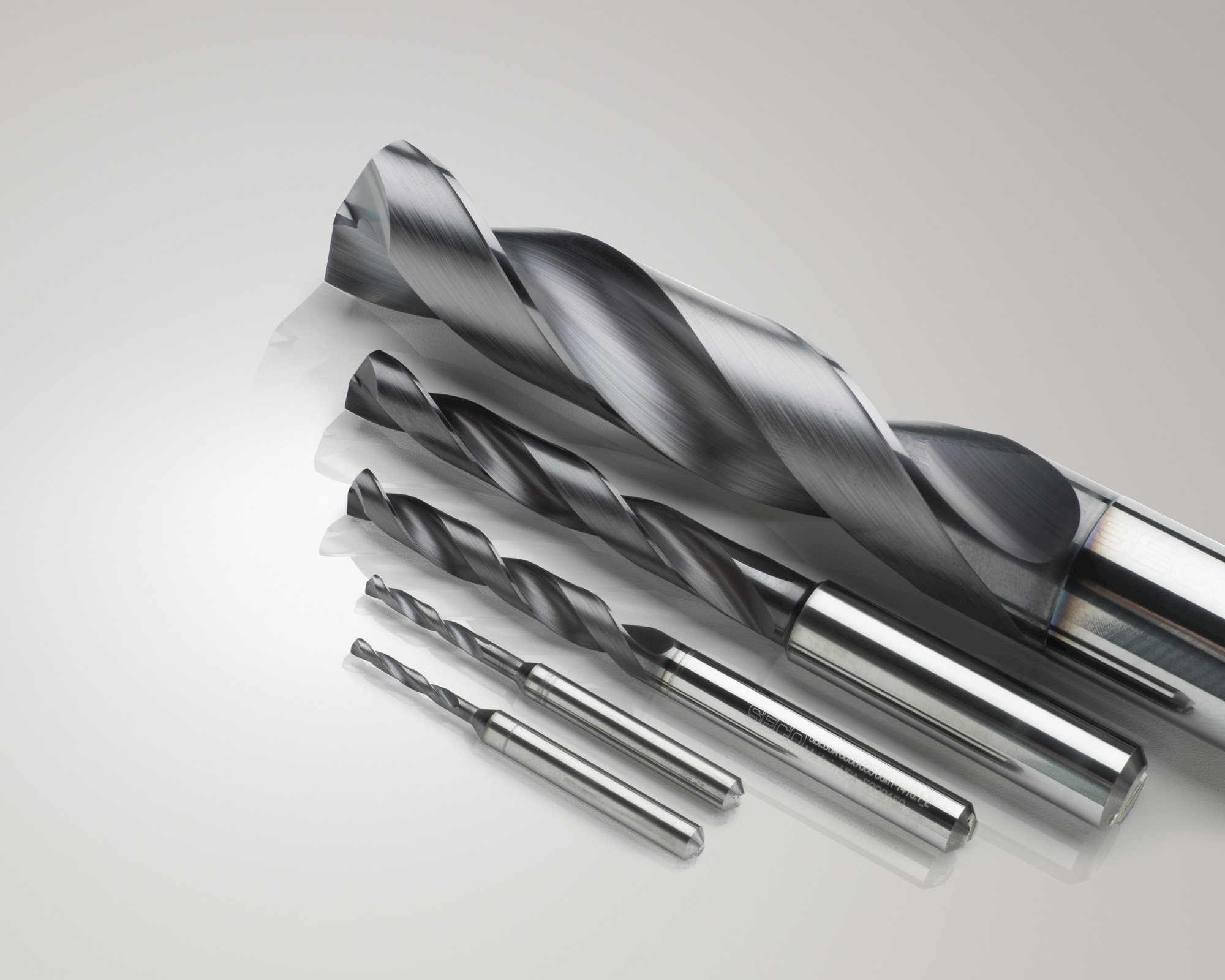

Seco offers several different drills tailored for tough materials. Solid carbide drills, such as Seco’s Feedmax™, are ideal for hardened steel and titanium, due to their rigidity and wear resistance.

For extreme hardness and heat resistance, diamond-coated drills are suitable for highly abrasive composites, while PVD-coated tools work best in the high-speed drilling of hardened steel and heat-resistant alloys.

Another option, universal drills offer a balanced performance but with trade-offs. “They will cut difficult-to-machine materials, but maybe not for so long,” Payling warns.

They can be effective for small to medium workshops, though, whereas specialized tools are better suited for large-scale operations with high drilling volumes.

For maximum efficiency, Payling recommends adhering to essential machining principles.

Machine capabilities are a primary consideration – high-performance machines with through-coolant spindles and sufficient pressure enable precision machining.

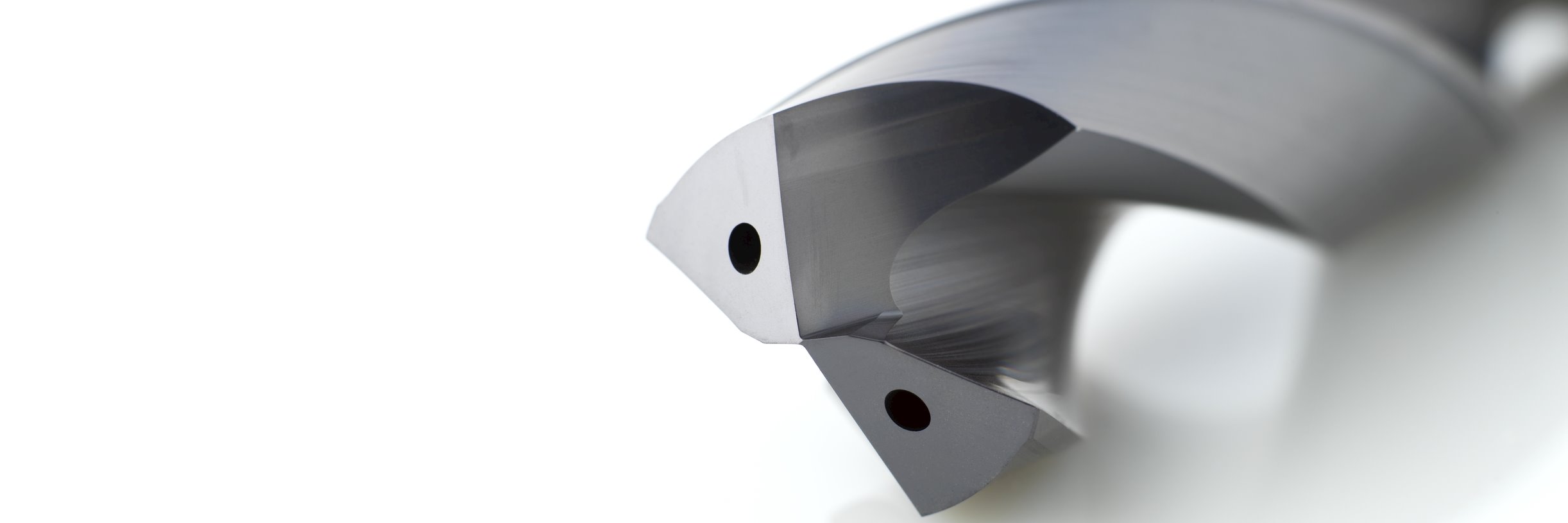

Material properties also require close consideration, as understanding their chemical composition can help the machinist anticipate potential challenges. So, follow supplier recommendations, Payling advises, adding that selecting the correct drill geometry matched to the material’s characteristics can significantly improve tool life and overall performance.

Additionally, proper spindle size, tool holders and optimized cutting parameters help ensure accuracy and stability. Trial runs also provide a valuable opportunity to refine settings before full-scale production, Payling advises. “Drill a few holes on a piece of material and see how it performs. Then you can tailor things before you start machining components,” he adds.

It is also important to monitor flank wear, as tough materials accelerate tool degradation. Machinists can detect wear early on by using a microscope or eyeglass. Payling recommends removing drills after 0.2mm flank wear, to prevent excessive chipping and maintain performance.

Finally, prioritizing accuracy over machining speed is essential with tough materials. “Machining speed is less important than accuracy. Tool longevity and proper setup should take precedence over cycle time,” says Payling.

Drilling tough materials demands a combination of high-quality tools and the best working techniques. “First, make sure everything’s clamped down and rigid, because a stable setup prevents vibration and misalignment. And clean the tool holder between changes, keeping everything surgical-level clean, as the smallest factors can affect tool life dramatically.

When drilling deep holes, it’s crucial to reduce the RPM significantly when entering the pilot hole. “We recommend setting the RPM to a maximum 100 RPM or lower to prevent any potential whip,” Payling suggests. “Solid carbide drills are heavy, and in horizontal applications they are also prone to droop, so a low RPM at startup is particularly necessary - starting the spindle at the recommended cutting RPM risks causing excessive whip, which can cause drill breakage.”

Internal coolant is also key, especially in deep or high-friction applications, as it prevents overheating and helps with chip evacuation. And for particularly deep or tough materials, series drilling helps reduce the load on the longest drill and provides better all-round tool life.

Monitoring wear and ensuring reconditioning occurs at the right time are other aspects of a successful drilling operation. Outer corner wear can signal excessive speed, since the peripheral speed is higher than the center, so reducing rotation speed can also extend tool life in certain conditions.

Proper tool maintenance helps to prolong tool life and improve machining efficiency. By keeping equipment clean, regularly checking for wear and following regrinding protocols, engineers can maximize performance while also reducing material waste.

Daily maintenance practices include cleaning drills after each use to remove material buildup, inspecting tools for chipped edges or coating discoloration, and storing tools in a protective environment to prevent chipping.

Regrinding is another element in extending tool life. “Three regrinds has become the norm today,” Payling says. “Use a reputable regrind company and check that they understand Seco geometries and coatings, and that they’re replicating as near to new as possible.” He also advises reconditioning tools before excessive wear for sustainability.

Even with the best planning, drilling challenges can arise, requiring troubleshooting techniques that can save time and reduce material waste. “Look for flank wear,” Payling says. “You can’t get away from it – it’s inevitable – but if it’s even across the drill point, it indicates a good setup.”

Other issues to monitor include edge chipping, often caused by vibrations or insufficient cooling, outer corner wear resulting from excessive speed, and center damage, which may be a sign of overfeeding. If you’re getting damage in the center, you should check whether the feed rate is too high. And lastly, monitor your tools and techniques regularly and be ready to make adjustments to help improve precision and prevent tool failure.

Drilling tough materials requires specialized tooling, refined machining strategies, and diligent maintenance. Seco’s solutions – from optimized drill geometries and coatings to expert support – help manufacturers tackle the complexities of drilling difficult materials. Implementing Seco’s recommended techniques and tool selection strategies will ultimately help achieve superior results, increase productivity and extend tool life.

Inline Content - Gridded Links

Tags: 'solid carbide drills'

Max links: 1