High Feed vs Conventional Milling: Making the faster choice

Compare high feed and conventional milling methods to see how you can boost your productivity and efficiency. Read our blog now!In today’s manufacturing landscape, success is nearly always determined by speed.

Most manufacturers looking to win more market share want to make more parts, in less time, with less machinist invention. If this is your ambition too, then your conventional milling set-up could be holding you back.

In this blog, we’ll explain why high feed milling could be the answer. We’ll also explore how high-feed tools can bolster productivity and elevate your current machining practice.

In simplest terms, high feed milling helps machinists unlock more from their machines than ever before.

In simplest terms, high feed milling helps machinists unlock more from their machines than ever before.

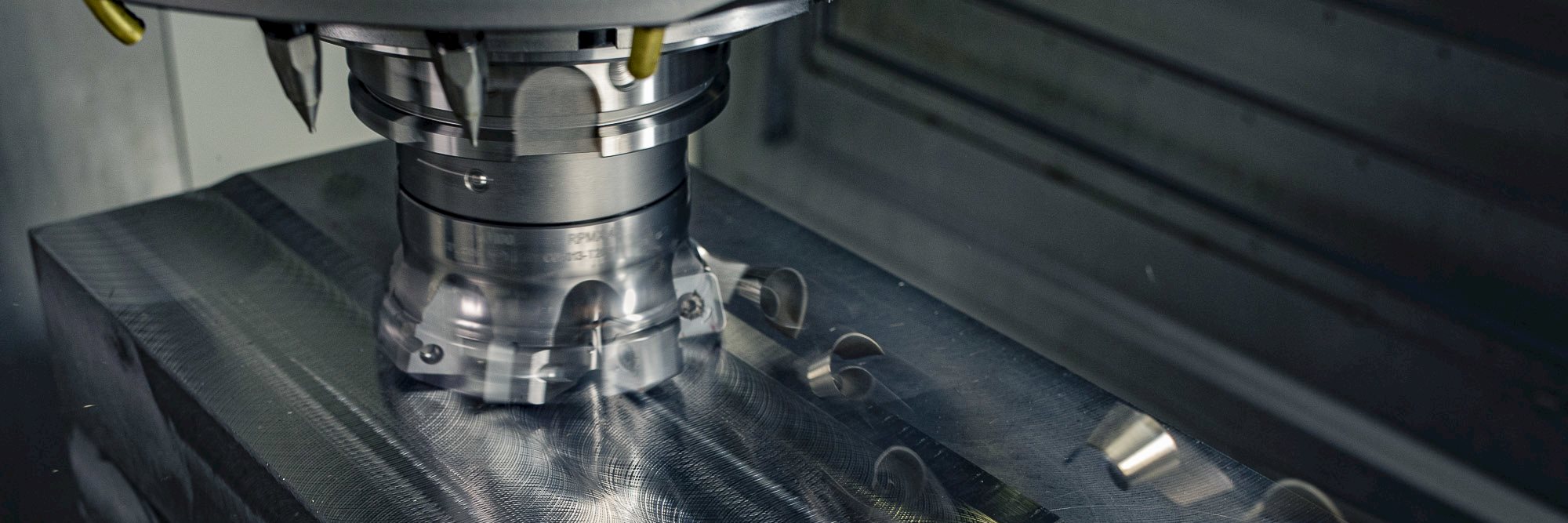

In fact, Seco’s High Feed SP cutters can help you achieve up to three times more machining speed than conventional tooling set-ups.

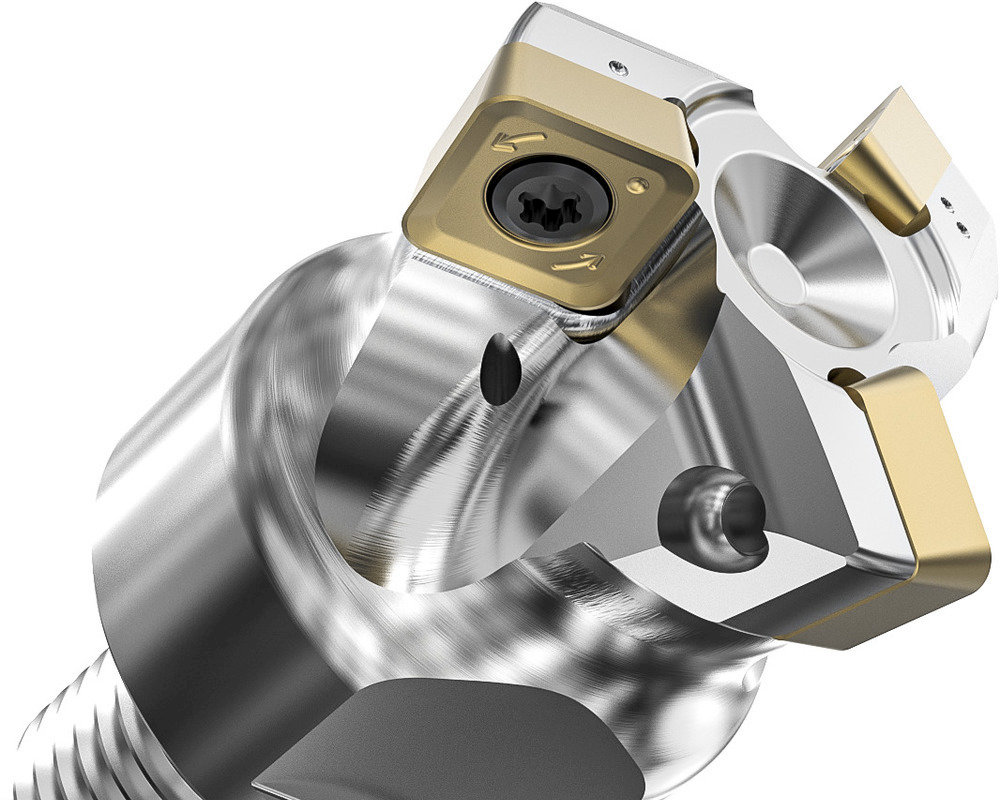

High feed milling maximizes material removal with shallow depths of cut and aggressive feed rates.

It’s a powerhouse solution for roughing, reducing cycle times, and extending tool life—helping to dramatically increase your production speed and market competitiveness.

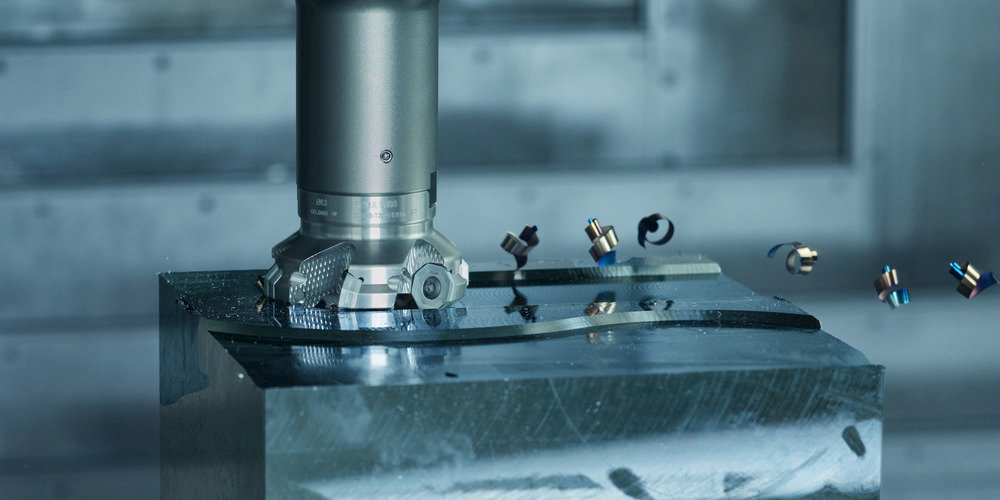

With a small lead angle and high feed per tooth, high feed cutting forces are redistributed to reduce wear and increase stability. Chips are thin and easy to evacuate, minimizing heat buildup—crucial for cutting tough materials like titanium and stainless steel.

High feed mills are fantastic for your most intensive machining applications, especially when working with demanding materials and high tolerances.

Roughing operations | Delivers faster material removal and shorter cycle times for roughing jobs, increasing productivity. |

Challenging materials | Cuts through stainless steel, heat-resistant allows, and titanium with ease. |

Deep Pocketing and 3D Profiling | Handles intricate geometries with stability and precision. |

Manufacturers aren’t just hungry for speed gains; they’re also seeking more sustainable machining outputs. This is another critical area where high feed mills can support your business.

High feed milling drastically reduces downtime and machinist intervention - meaning fewer tool changes, slashed material waste, and lessened production errors.

What does this translate to? Faster, more streamlined machining preserves energy and costs, meaning more widely sustainable production—especially when working at volume.

There’s no doubt that high feed milling is more progressive than conventional milling, but these tools still remain a vital part of any manufacturer’s inventory, thanks to their general versatility and precision.

When machining speed and tool optimization aren’t the ultimate goal, conventional milling delivers thanks to its reliable control and accuracy.

Here are some excellent machining applications for your conventional milling inventory.

Face Milling | When creating flat surfaces, the cutter rotates effortlessly against the feed direction to ensure a smooth finish. |

Slot Milling | Conventional milling is effective for creating narrow channels and slots in a workpiece. |

High feed milling is the dominant force in modern machining, delivering unmatched speed, efficiency, and sustainability gains.

However, conventional milling still plays a key role in precision work and finishing.

The smartest shops leverage both—using high feed milling for aggressive roughing, and conventional milling for more refined work. If speed and productivity are your end game, high feed milling is the smarter, faster choice.

Discover how to outpace the competition with our latest high feed white paper.

Download your free copy here