How to Achieve High Quality Threads - Tapping and Drilling Synergy

Prevent tap breakage and thread defects by optimizing drilling accuracy and tapping techniques for reliable, high-precision internal threads.Achieving consistently high-quality threads in machining is essential for the reliability and performance of any manufactured component. While the tapping operation often receives the most attention, the importance of the drilling process cannot be underestimated. In fact, the drilling stage lays the foundation for successful tapping; any inaccuracies or defects introduced during drilling can have a domino effect, leading to problems such as scraped parts, broken taps, and increased production costs. We begin with exploring the critical relationship between drilling and tapping, providing expert insights and actionable advice on how to ensure optimal drilling practices for excellent thread quality.

The drilling operation is, without a doubt, the starting point for any threading process. Just as a flawed foundation compromises the structural integrity of a building, a poorly executed drilling process undermines the quality of the threads that follow. The drill creates the initial hole into which the tap will cut or form the threads, and the accuracy and condition of this hole are paramount.

As Ricky Payling, Global Product Manager for Drilling at Seco, emphasizes, “Good quality threads begin with good quality holes” highlighting the fundamental connection between the two operations.

Several common drilling issues can negatively impact the subsequent tapping operation and the quality of the final thread. Understanding these issues and knowing how to address them is crucial for machinists.

Incorrect Hole Size: One of the most common pitfalls is drilling a hole with an incorrect diameter. If the hole is too small, the tap will have to remove excessive material, leading to increased stress and a higher risk of tap breakage. An undersized hole can create a very tight thread and even cause failure of the tap due to the increased pressure. On the other hand, a hole that is too large will leave insufficient material for the threads, resulting in weak or shallow threads that may not meet the required strength or fastening specifications. The solution lies in precision: “We would always recommend you look into what the recommended drill size is for the particular manufacturer of tap,” advises Ricky. While there are rules of thumb, these don't apply universally, especially for specialized taps like those used with Helicoil inserts or forming taps.

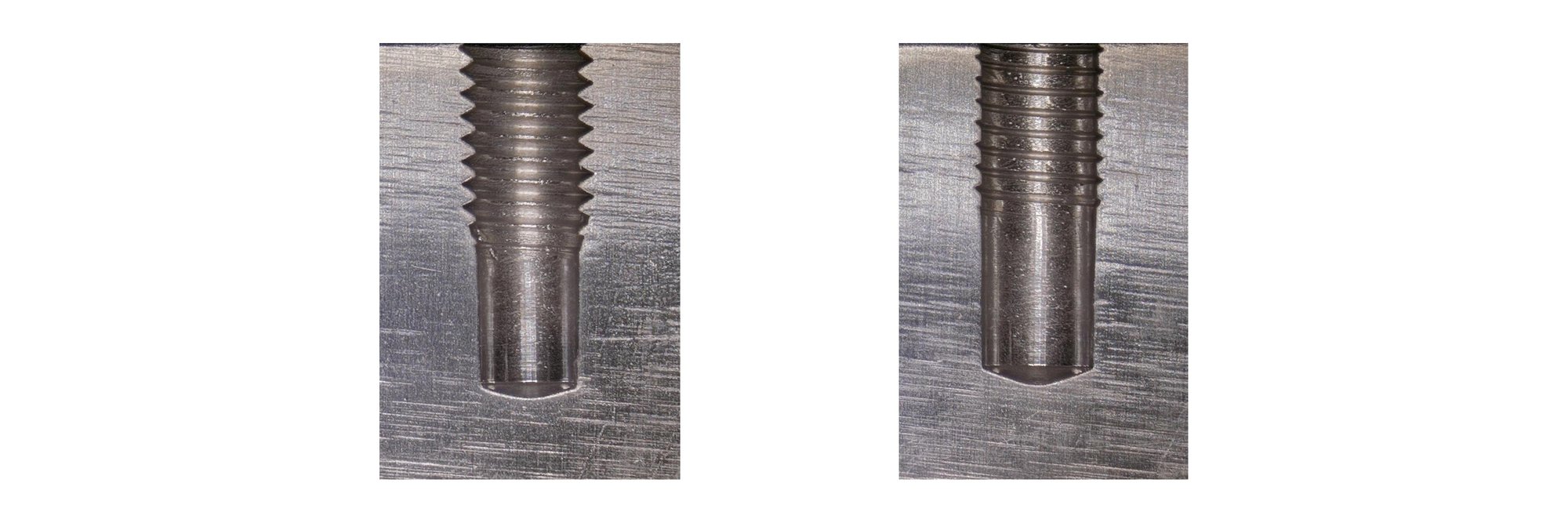

Poor Hole Quality: The quality of the drilled hole's finish and geometry is also critical. Issues like burrs, rough surfaces, or work hardening can create obstructions for the tap, leading to poor thread finish, increased tool wear, and even tap breakage.

Insufficient or Incorrect Coolant Application: Heat generation is an unavoidable part of the drilling process, and if not managed correctly, it can negatively affect both the drill and the workpiece. Excessive heat can cause work hardening, making the material more difficult to tap and can also lead to premature tool wear. To mitigate this, proper coolant application is essential. As Ricky points out, coolant feed drills are highly beneficial as they help reduce temperature when drilling. Furthermore, coolant also aids in chip evacuation, preventing chips from interfering with the tapping process.

To ensure the best possible foundation for tapping, several best practices should be followed during the drilling operation:

Select the Right Tools: Investing in high-quality drill bits is essential. Universal drills are suitable for a range of materials, but for specific materials like stainless steel, drills with specialized geometries are recommended to guarantee that you get a good quality hole. Step drills can also be advantageous, as they combine drilling and chamfering in one operation, reducing the starting force when the tap begins to cut the material.

Once a precise and high-quality hole has been created through drilling, the tapping operation takes center stage in producing the internal threads. Tapping, while seemingly straightforward, requires careful consideration of several factors to ensure the creation of accurate, strong, and consistent threads. Just as drilling has its nuances, tapping presents its own set of challenges and best practices.

Even with a perfectly drilled hole, several issues can arise during the tapping process, compromising the quality of the final thread.

Tap Breakage: This is a common and costly problem in tapping operations. As Radosław Zdanowski, Global Product Manager for Tapping at Seco, explains, tap breakage can occur due to several reasons, including an undersized hole, insufficient lubrication, excessive cutting speed, or problems with chip evacuation. An undersized hole forces the tap to work harder, increasing the risk of breakage. Insufficient lubrication leads to increased friction and heat, which can also cause the tap to fail. Excessive cutting speeds can overload the tap, while poor chip evacuation can cause chips to pack around the tap, leading to breakage and poor thread quality. To mitigate these risks, it is essential to begin with fundamental principles to avoid scrapping a component. This includes proper tap selection, ensuring the correct drill size, adequate lubrication, appropriate cutting speeds, and effective chip control.

Poor Thread Finish: A rough or torn thread finish is another undesirable outcome of tapping. This can often be attributed to dull taps, inadequate lubrication, or incorrect cutting speeds. Dull taps tend to tear the material rather than cut it cleanly, resulting in a poor finish. Insufficient lubrication increases friction and heat, which can also contribute to a rough finish. Incorrect cutting speeds can lead to chatter and vibration, further deteriorating the thread quality. Using sharp taps, ensuring proper lubrication, and optimizing cutting parameters are essential for achieving a smooth and accurate thread finish.

Chip Control: Managing chip formation and evacuation is critical in tapping, especially in blind holes. Long, stringy chips can become entangled around the tap, hindering the cutting process, causing tool breakage, and affecting thread quality. This is particularly problematic with materials that produce long, continuous chips, such as stainless steel. For blind holes, spiral flute taps are ideal as they evacuate chips upward toward the shank, preventing clogging. For through-holes, spiral point taps push chips forward with the feed, out the other side. Selecting taps with appropriate flute designs that facilitate chip forming and evacuation is essential. Techniques like peck tapping, where the tap is periodically retracted to break the chips, can also be employed.

To optimize tapping operations and ensure consistent thread quality, several streamlining strategies can be implemented:

Select the Right Tap for the Job: Choosing the correct tap for the specific material and application is essential for efficient and successful tapping. If you need flexibility, universal solutions are often a great choice. The Seco universal tapping range includes several high-quality options designed for diverse tapping needs. For a cost-effective solution, consider the T30 General Purpose Tap. The T32 Universal Tap provides excellent versatility across various materials, and for a chip-free alternative, explore the benefits of our T33 Forming Tap. When tackling more demanding applications, our T34 High Performance Versatile Tap is engineered to deliver exceptional results.

By carefully considering these factors and implementing best practices, machinists can significantly improve the efficiency and quality of their tapping operations, minimize waste and maximize productivity.

Achieving high-quality threads is not solely about the tapping operation. It's a synergistic process where the precision and quality of the drilled hole directly influence the outcome of the tapping stage. By understanding the critical factors in both drilling and tapping and implementing best practices, machinists can significantly reduce scrap, extend tool life, and produce consistently high-quality threads. Leveraging high-quality tooling solutions, such as the Seco universal drilling and tapping ranges, can further enhance efficiency and ensure reliable operations.

Webinar: How to Achieve High-Quality Threads in Machining | Seco Tools