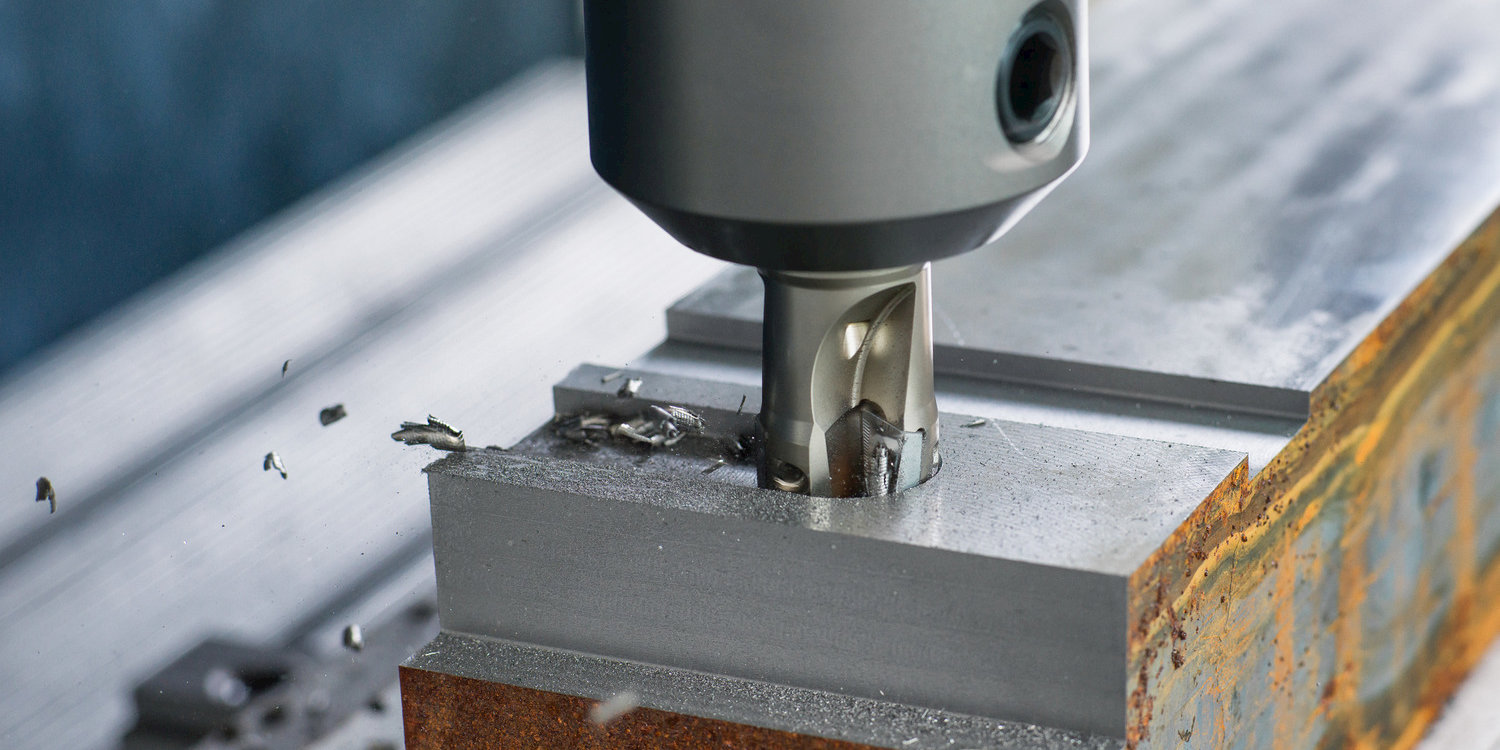

MK1501 Milling grade delivers consistent, predictable performance

Get results with MK1501 when machining cast iron, grey cast iron and ductile cast iron. Visit our website to learn more about these durable insertsWhether you have coolant in your machining setup or not, the MK1501 grade works well in both wet and dry conditions. This is great for customers who may need to machine dry but also require coolant for effective chip evacuation and heat management. The MK1501 grade's performance is constant, providing reliable results regardless of application.

Your Challenge:

You don’t have to use coolant when machining cast iron but it can help in some situations where there is a need for more effective chip evacuation or to handle the heat.

Our Solution:

Luckily, the MK1501 grade works great whether you use coolant or not. This makes it more versatile and ensures you get reliable results and a consistent performance no matter what.

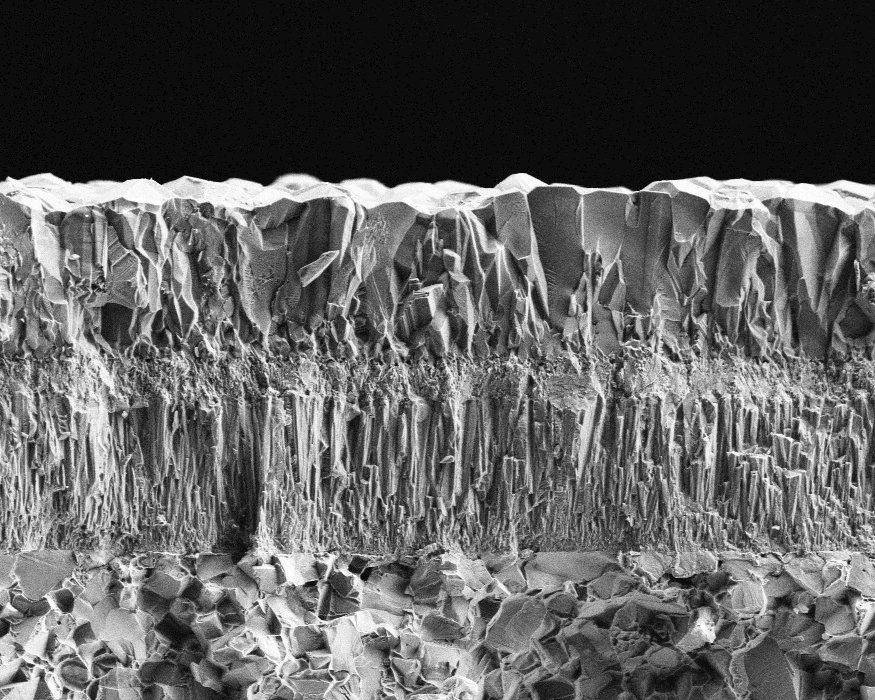

The chrome-colored MK1501 grade is the newest generation of Duratomic® inserts with a CVD coating. They are built to last longer and resist wear.

The chrome-colored MK1501 grade is the newest generation of Duratomic® inserts with a CVD coating. They are built to last longer and resist wear.

Plus, the cutting edges change from chrome color to black when it is worn out, so you can easily tell when it's time to replace them.

This means you'll get the most out of each insert, boosting productivity and cutting down on tooling costs.

Your Challenge:

Many customers find that their tools don't last as long, or they wear out unevenly when milling cast iron. This leads to a lot of wasted inserts and an unreliable process.

Our Solution:

The MK1501 grade's new post-treatment processes make it tougher, so you're less likely to deal with sudden insert breakages, while the used edge detection feature helps you use every edge of the insert, so you won’t throw it away too early – boosting your productivity.

The new post-treatment processes of the MK1501 grade make it tougher, meaning the wear is predictable and increases the opportunities for unmanned production.

Plus, with the MK1501 grade, you get more precise cutting data recommendations for cast iron materials, especially when machining grey cast iron and ductile cast iron.

Your Challenge:

You need to increase your productivity and reduce costs to stay ahead of the competition.

You can't afford unpredictable performance and machine downtime because of unforeseen tool changes and broken inserts.

Our Solution:

The MK1501 grade's high heat resistance and increased wear resistance allow for higher cutting speeds, leading to shorter cycle times and better productivity when milling cast iron.

This leads to impressively predictable wear behavior.