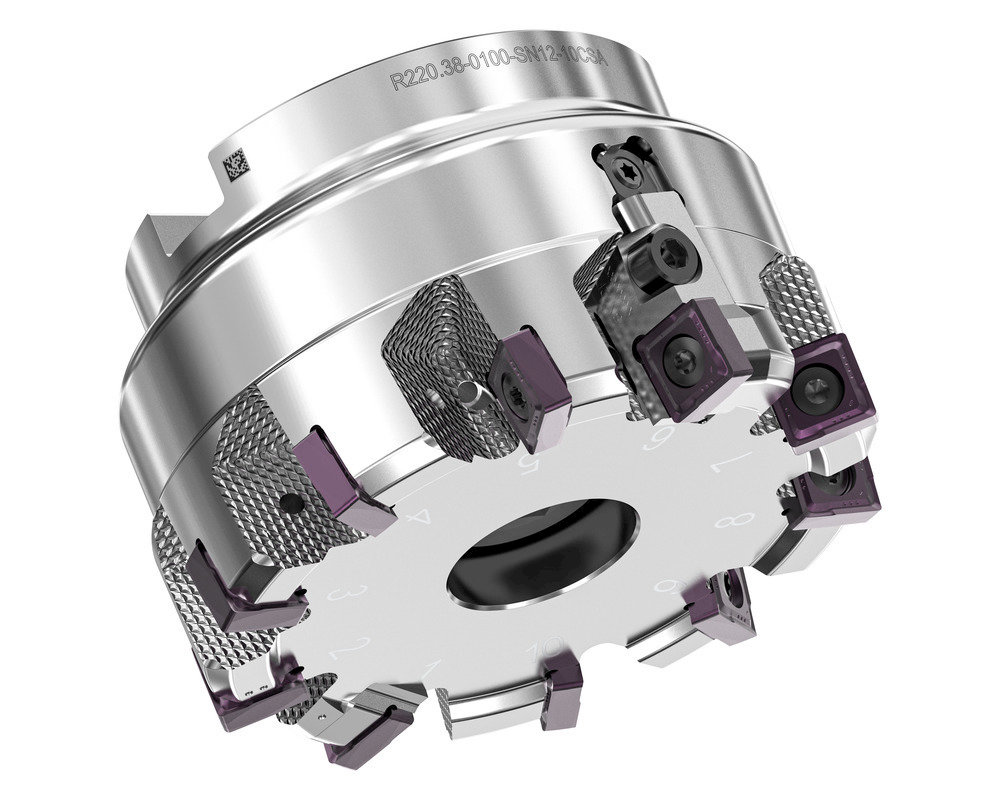

The .38 Face Finishing Milling cutter engineered for smooth surfaces

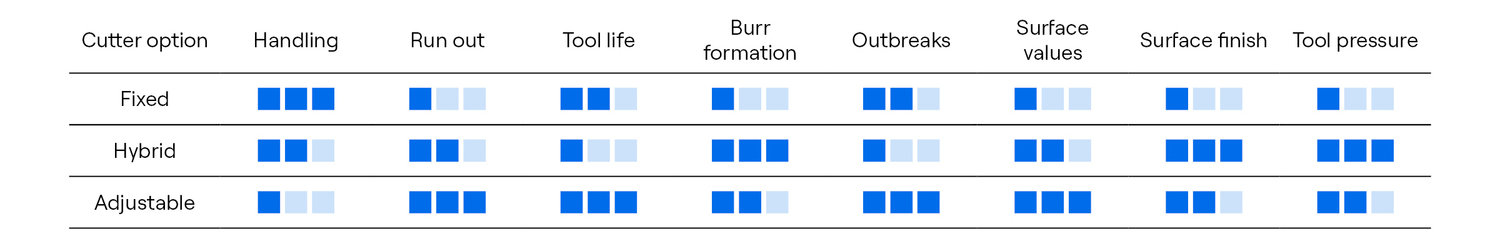

For flawless surface finishes, check out our new face finishing cutters – in fixed, hybrid and adjustable types. Which one will you choose?

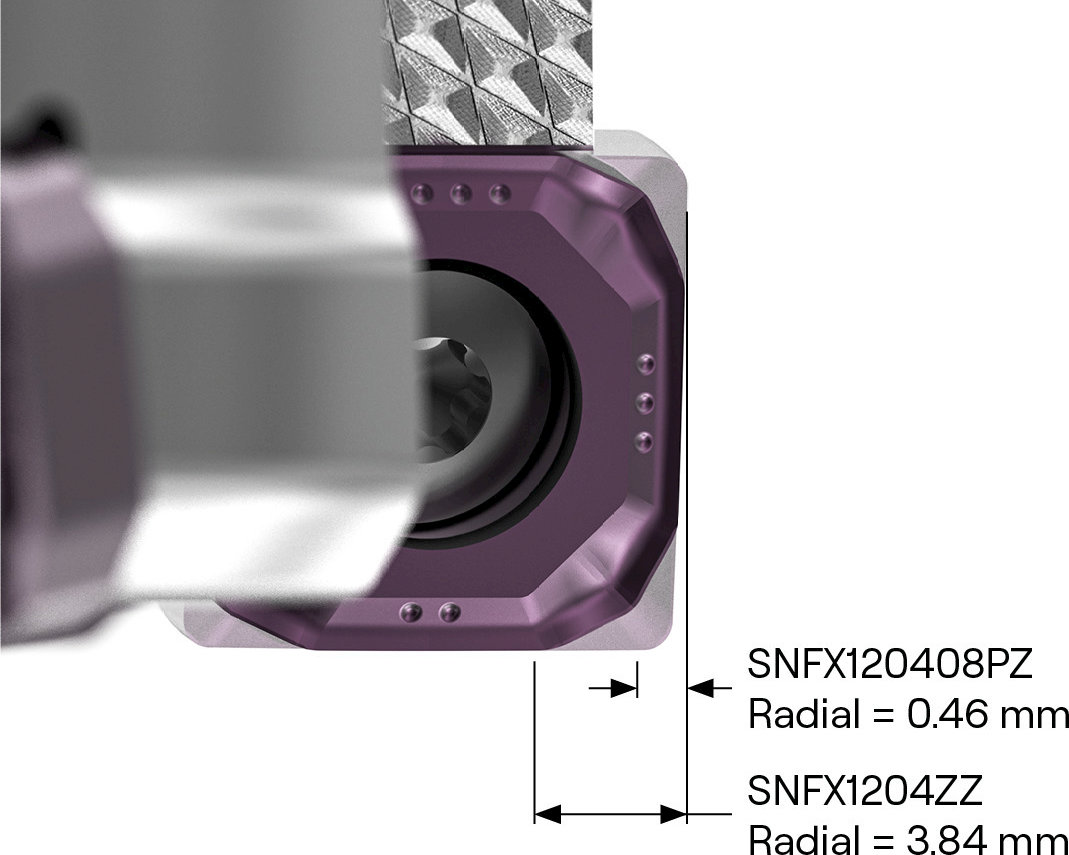

Each cutter works with two insert types: one with an 88° lead angle for near-wall machining, and another with a 27° lead angle for high-feed, open-surface work.

With just one system and two insert styles, you can tackle a wide range of finishing challenges while keeping things simple, efficient, and cost-effective.

Keep reading for more detailed information on each cutter variation.

The fixed pocket cutter is designed for effortless handling and setup-free operations.

The fixed pocket cutter is designed for effortless handling and setup-free operations.

With a tilted screw design that ensures perfect insert self-centering, this cutter delivers excellent run-out accuracy (4–15 µm) and is ideal for users who want high surface finish quality without the hassle of adjustments—making it a cost-efficient milling solution that reduces setup time, operator error, and the need for training.

Inline Content - Gridded Links

Tags: '.38 - sa fixed pocket - screw clamping'

Max links: 1

Your Challenge

Setting up cutters and adjusting inserts to the correct height can be time-consuming, error-prone, and require skilled labor—especially in high-precision finishing.

Our Solution

The fixed pocket solution eliminates the need for manual adjustments. Just mount and go—achieving reliable, repeatable results with minimal effort.

The hybrid cutter combines the best of both worlds: fixed pocket inserts and cassette pockets that can be adjusted if needed.

It offers a balanced solution for users who need improved surface finish and reduced burr formation without the complexity of full adjustability.

The cassette inserts create the smooth surface finish, while the fixed inserts handle the material removal—resulting in lower tool pressure and excellent chip control.

This makes it perfect for applications where surface quality and ease of use must co-exist.

Inline Content - Gridded Links

Tags: '.38 - csa hybrid pocket'

Max links: 1

Your Challenge

Achieving a high-quality finish while minimizing burrs and tool pressure—without complicating the setup process.

Our Solution

The hybrid cutter delivers a smart balance of performance and simplicity. It reduces burrs and improves finish while keeping handling straightforward.

For the most demanding finishing applications, the adjustable cutter offers unmatched precision and tool life.

Each pocket can be fine-tuned to achieve run-out as low as 0–2 µm, enabling mirror-like surface finishes even at high feed rates.

This cutter is ideal for experienced users who need full control over every detail of the milling process and are willing to invest in setup time for superior results.

Inline Content - Gridded Links

Tags: '.38 - hsa adjustable pocket', '.38 - hsa adjustable pocket'

Max links: 1

Your Challenge

When surface finishing requirements are extreme, even minor setup errors can lead to costly rework or scrap.

Our Solution

The adjustable cutter gives you full control over run-out and insert positioning, ensuring the highest possible surface quality and tool longevity.