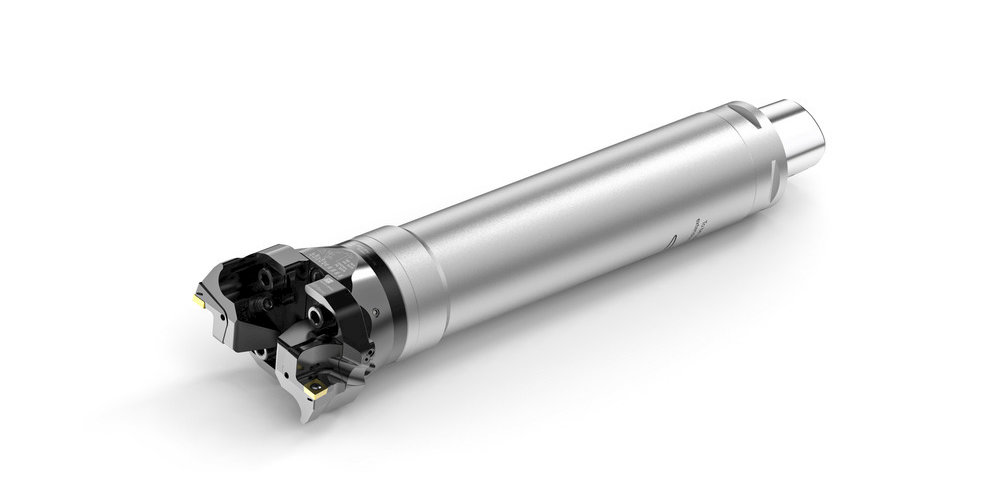

BB732 Boring Bridges – Engineered for deep hole Boring with Steadyline® Bars

BB732 Boring Bridges for deep boring in large diameters. Control vibrations in roughing and finishing. Learn more about the range here. The BB732 bridges support both roughing and finishing operations, eliminating the need for separate tools and reducing inventory costs. This dual-functionality makes them a cost-effective solution if you are looking for flexibility without sacrificing performance.

The BB732 bridges support both roughing and finishing operations, eliminating the need for separate tools and reducing inventory costs. This dual-functionality makes them a cost-effective solution if you are looking for flexibility without sacrificing performance.

Your Challenge:

Needing separate tools for roughing and finishing increases costs and complexity.

Our Solution:

BB732 bridges offer a modular design that supports both operations, streamlining your tooling strategy and reducing overhead.

The BB732 Boring Bridges are engineered for seamless integration with Steadyline® SM40 bars, delivering unmatched performance in deep hole boring applications for larger diameters.

The BB732 Boring Bridges are engineered for seamless integration with Steadyline® SM40 bars, delivering unmatched performance in deep hole boring applications for larger diameters.

They are lightweight and modular, so you get the strength and stability without the bulk.

Thanks to the coolant flow targeted directly to the cutting edge, the BB732 is ideal for high-precision, high-efficiency operations.

Your Challenge:

Achieving deep boring with conventional heavy bridges often leads to tool incompatibility and poor machining outcomes.

Our Solution:

BB732 bridges are specifically designed for Steadyline® bars, enabling deep boring with lightweight, vibration-controlled assemblies.

The BB732 bridges, when paired with Steadyline® technology, offer up to three times greater dynamic rigidity than conventional holders. This ensures stable machining even with long overhangs, maintaining tight hole tolerances and delivering excellent surface finishes. The result? A boring tool that truly controls vibration and enhances productivity.

Your Challenge:

When working with long overhangs and unstable assemblies, vibration issues can easily compromise surface quality.

Our Solution:

Steadyline® technology with BB732 bridges minimizes vibration, enabling high-speed, high-precision boring even in challenging setups.

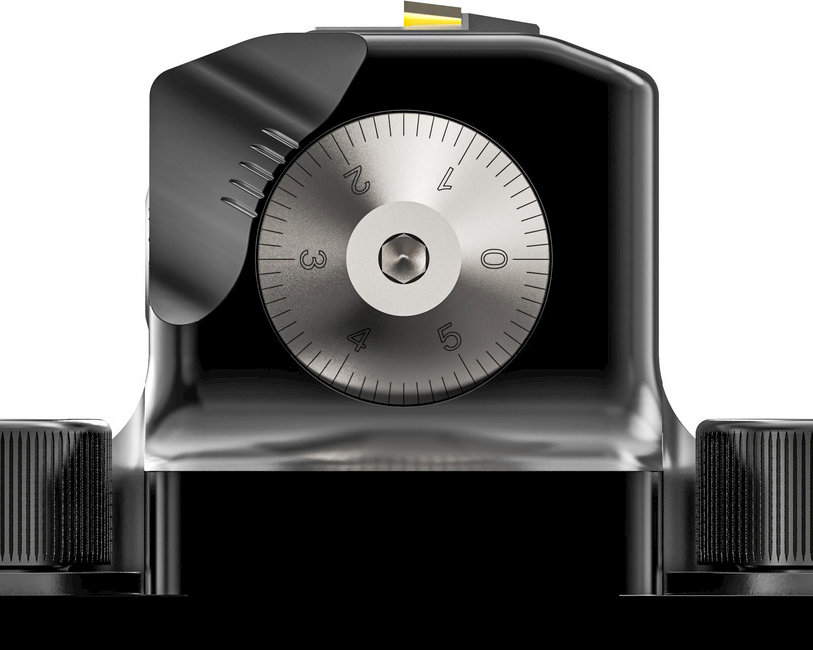

Every detail of the BB732 bridges is crafted with the user in mind.

From the vernier scale to laser-marked torque values and safety information, these features enhance usability and reduce set-up time.

The integrated safety stopper also prevents block ejection, ensuring a safe and reliable operation.

Your Challenge:

Complex setups and hard-to-read instructions slow down operations and increase the risk of errors.

Our Solution:

BB732 bridges feature intuitive markings and ergonomic design elements that simplify use and boost operator confidence.

In line with modern sustainability goals, BB732 bridges come with paperless documentation.

In line with modern sustainability goals, BB732 bridges come with paperless documentation.

A QR code provided with the product links directly to digital user instructions, reducing paper waste and ensuring that the latest information is always at your fingertips.

Your Challenge:

Managing physical documentation is inefficient and environmentally unfriendly.

Our Solution:

BB732 bridges support a paperless workflow with digital access to all product instructions via a QR code.

Inline Content - Gridded Links

Tags: 'bb732 bridge bars for steadyline'

Max links: 1