The DP2501 Grade – Drill in all applications, all materials and all conditions

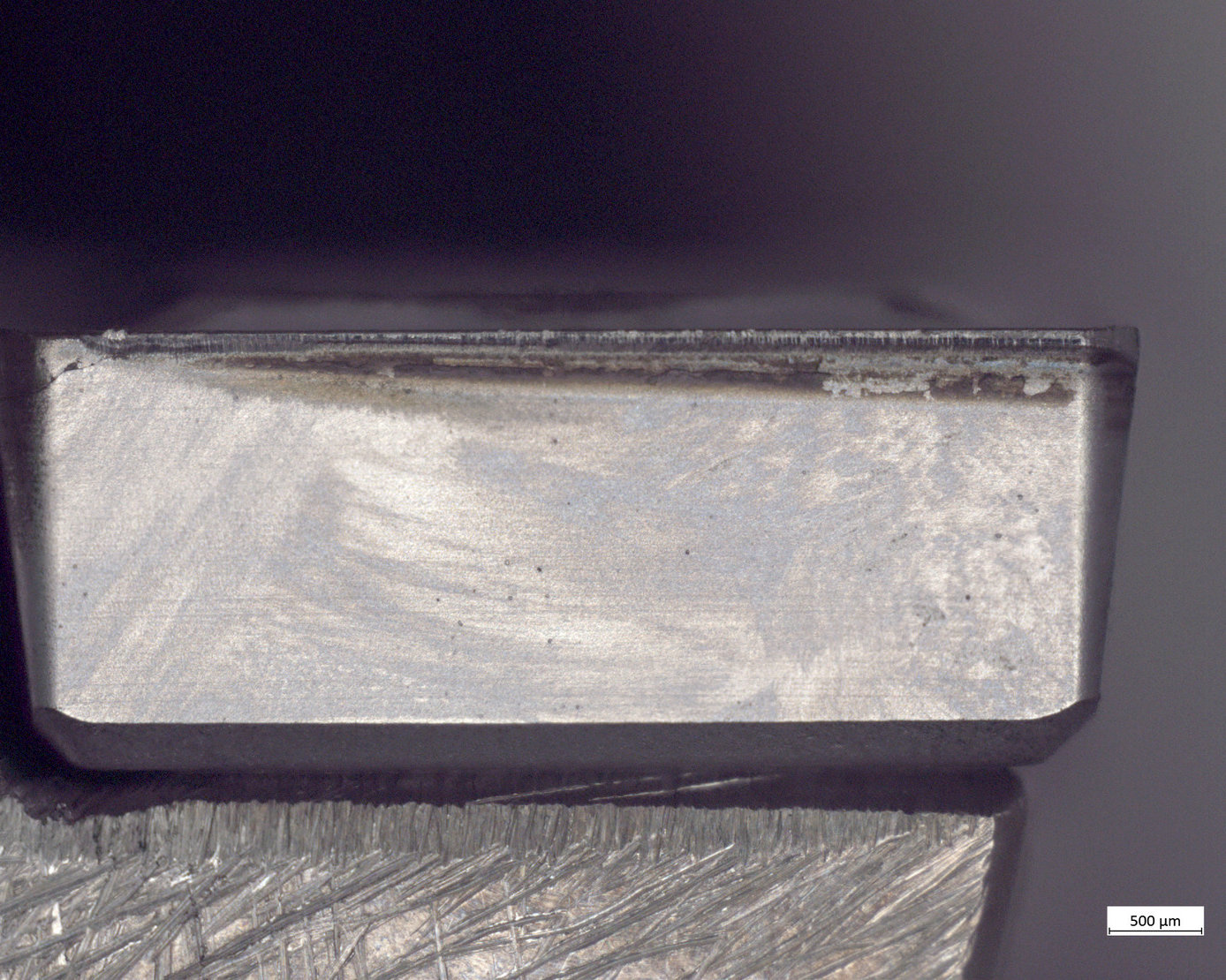

DP2501 grade ensures predictable drilling in deep hole operations excelling in both high and low cutting speeds. Learn more about DP2501 grade now! The chrome-colored use edge detection layer, meaning that the cutting edge change to black once worn out, so you can easily see if all edges on an insert have been used and when they need replacing.

The chrome-colored use edge detection layer, meaning that the cutting edge change to black once worn out, so you can easily see if all edges on an insert have been used and when they need replacing.

Perfect for eliminating the risk of broken inserts in the machine, which is just a huge inconvenience!

Your Challenge:

It can be hard to see which edges on an insert have or haven’t been used. And ensuring full usage of inserts can be time-consuming and lead to throwing away inserts too soon.

Our Solution:

The used edge detection feature of the DP2501 grade makes it easy to see if all edges on an insert have been used, ensuring full usage and ultimately saving costs.

The DP2501 grade is all about giving you a long and predictable tool life, thanks to the latest post-processing methods on the Duratomic® CVD coating.

This state-of-the-art post end treatment also gives a strong and tough edge line making it highly reliable even in tough drilling applications.

The inserts are also equipped with a Data Matrix Code so you can easily access up-to-date recommendations, ensuring you get precise cutting data for your selected workpiece materials.

Your Challenge:

You struggle to achieve reliable tool life in deep hole drilling applications (5xD) and/or intermittent cuts due to uneven cutting conditions and vibrations when using long drills.

Our Solution:

The DP2501 grade has a tougher edge line, which means it performs well even in unstable conditions. This ensures that your drilling process is reliable, and the tool lasts longer.

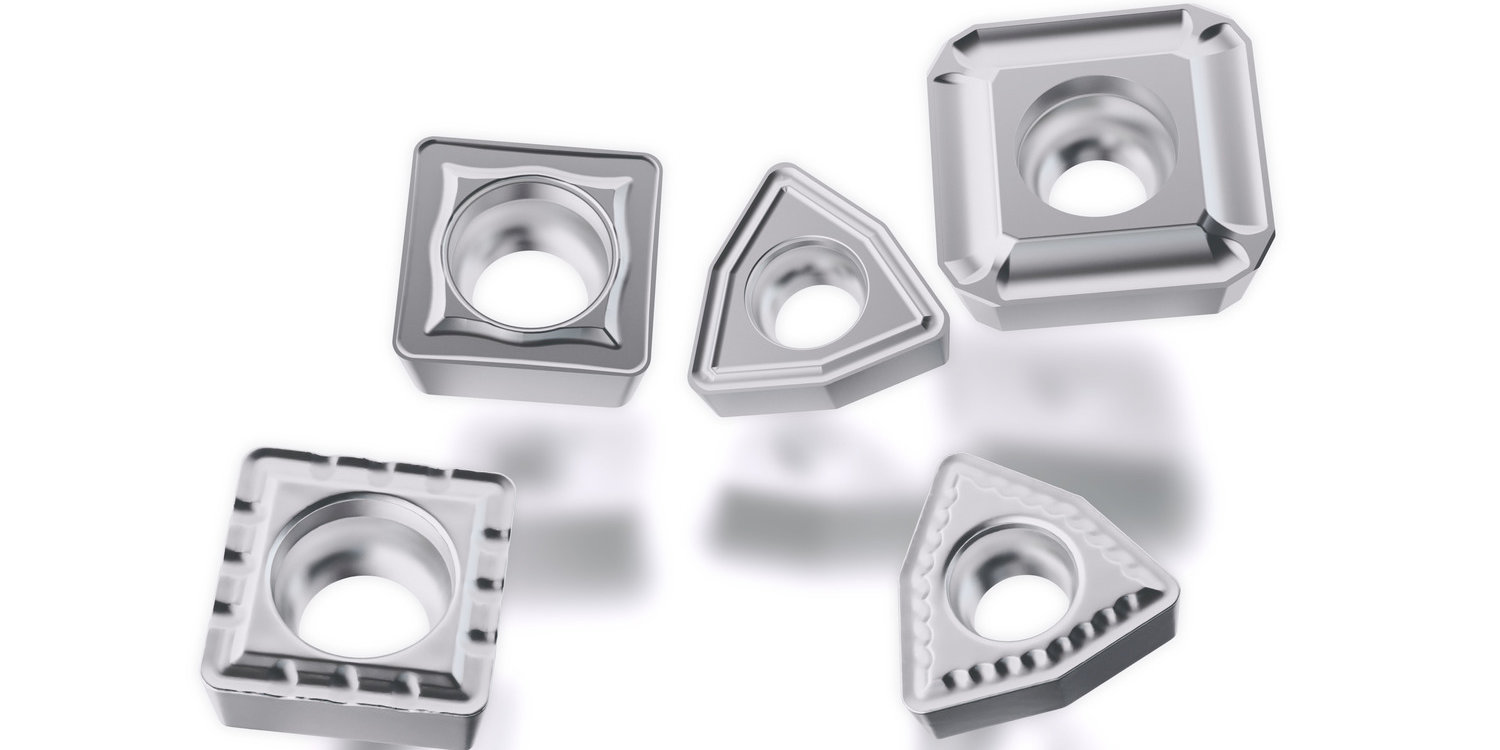

The DP2501 grade is a versatile grade that can cover all indexable drilling applications, offering peak performance in steel and stainless steel materials.

It minimizes the need for several specific insert grades, making it suitable for all drilling applications from shallow holes to maximum drilling depth. The strong yet durable cutting edge ensures reliable performance across various applications.

Your Challenge:

Choosing the correct insert grade for various workpiece materials can be difficult, and valuable machining time is lost during the process of indexing inserts.

Our Solution:

The DP2501 grade offers versatility, making the choice easy by being suitable for all materials, particularly steel and stainless steel. It also offers longer tool life, reducing the frequency of indexing inserts and allowing for increased unmanned production time.

The DP2501 grade includes a considerable amount of reclaimed carbide, and the inserts can be recycled after use.

Seco offers a buy-back program to promote circular economy practices which not only helps in reducing waste but also supports sustainable practices in drilling operations.

Your Challenge:

You want to be more sustainable but finding sustainable and cost-effective solutions for drilling operations can be challenging.

Our Solution:

The DP2501 grade's inclusion of reclaimed carbide and the availability of a buy-back program for recycling inserts support sustainable practices and reduce costs.