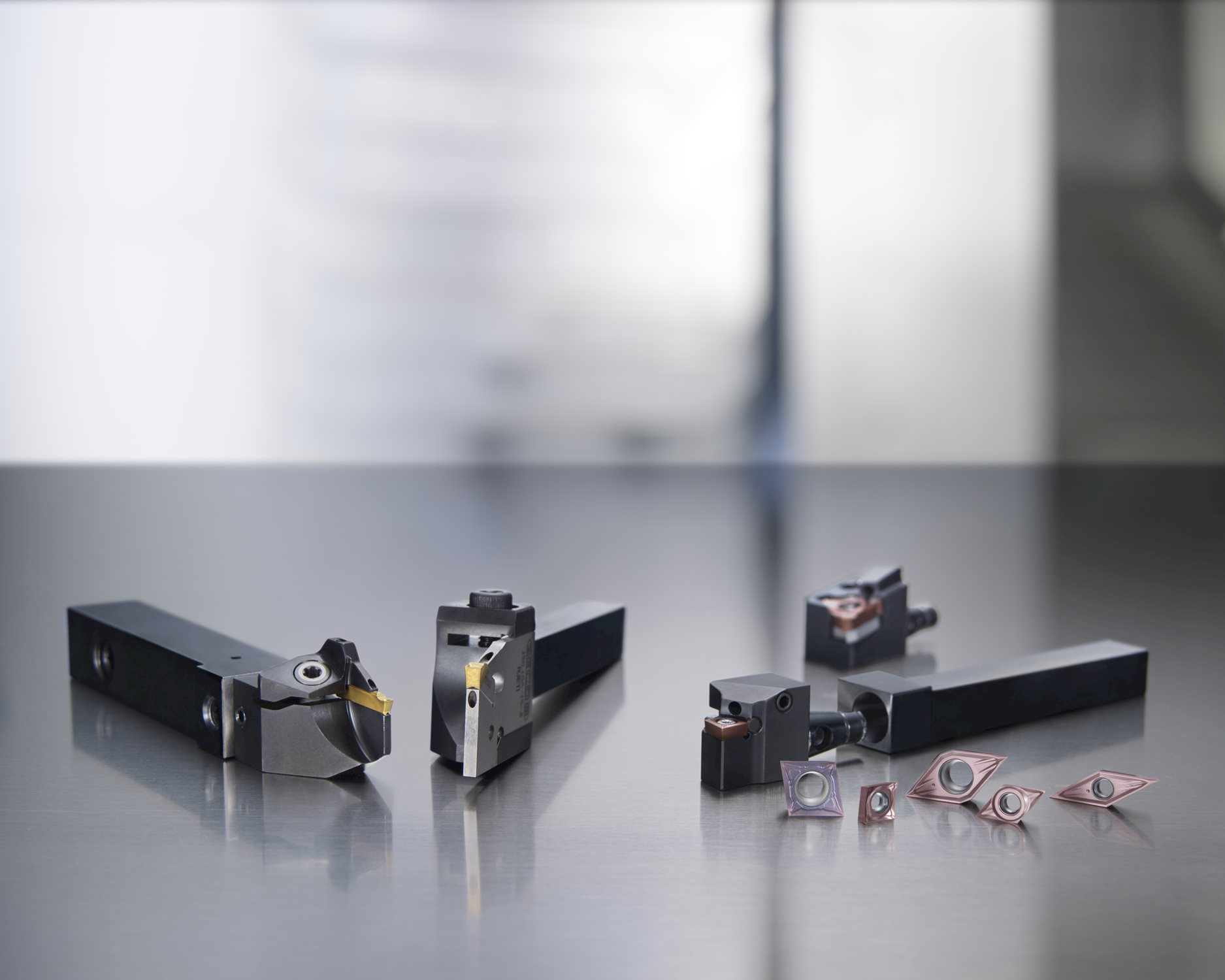

ELIMINATE HOLDER BREAKAGE WHEN ROUGHING WITH PCBN AND CERAMICS

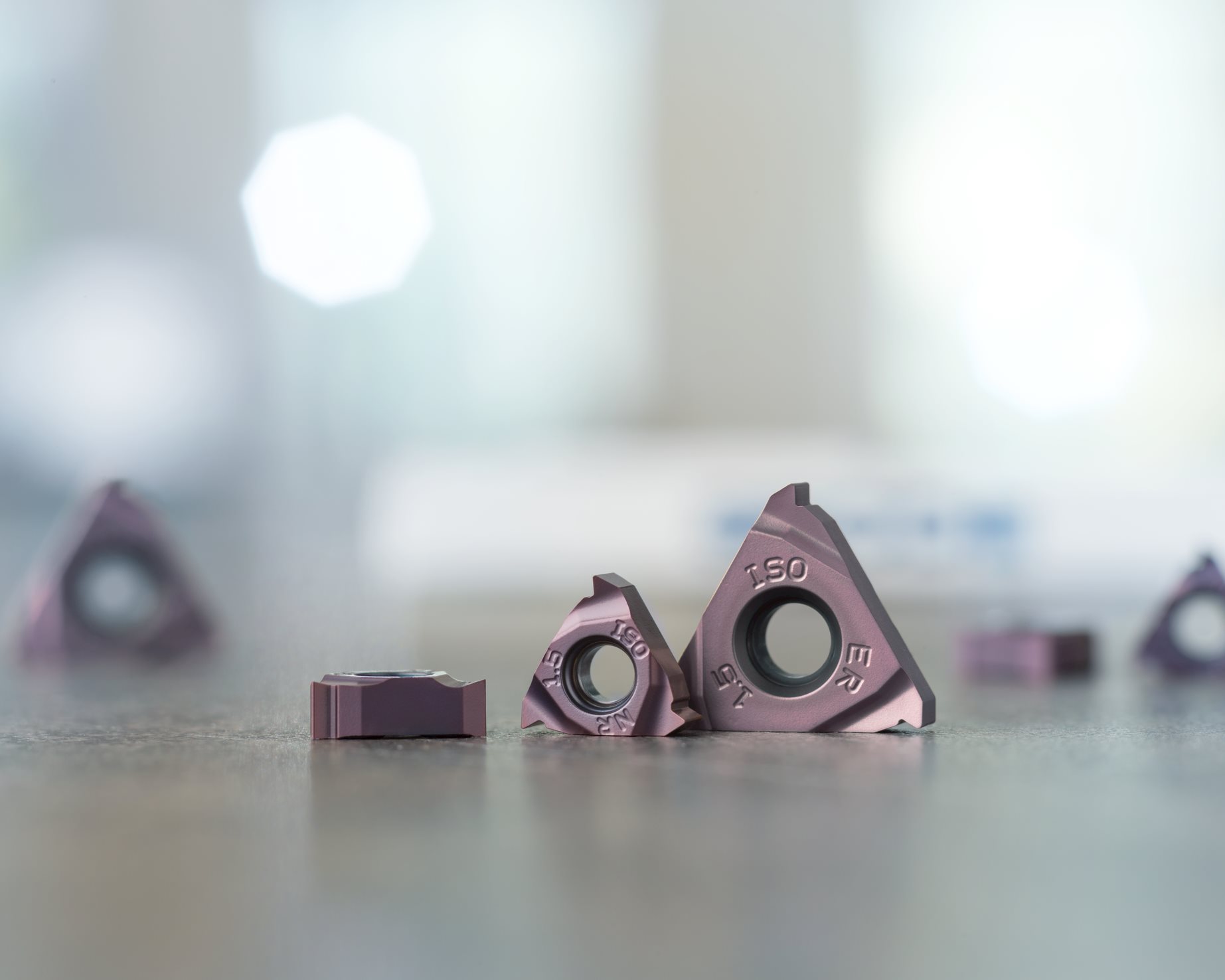

Brittle inserts can sometimes break, often taking expensive toolholders with them. Even though PCBN and ceramic inserts make it possible to achieve the highest material removal rate, breakages can be a problem in the most demanding applications.YOUR BENEFITS:

- Flexibility by using different cassettes/insert types in the same Seco-CaptoTM unit

- Reliable process due to hardened stainless steel cassettes reducing the risk of damaged pockets

- Cost savings as only the cassettes need replacing

- Keep processes on track due to quick cassette changes

- Frees up stock space

YOUR CHALLENGES:

- Insert breakage reduces the reliability of your heavy roughing operations in heat resistant super alloys, high chrome iron and high manganese steel applications

- Stocking sufficient holders for machining applications with high levels of tool wear takes up too much space

OUR SOLUTIONS:

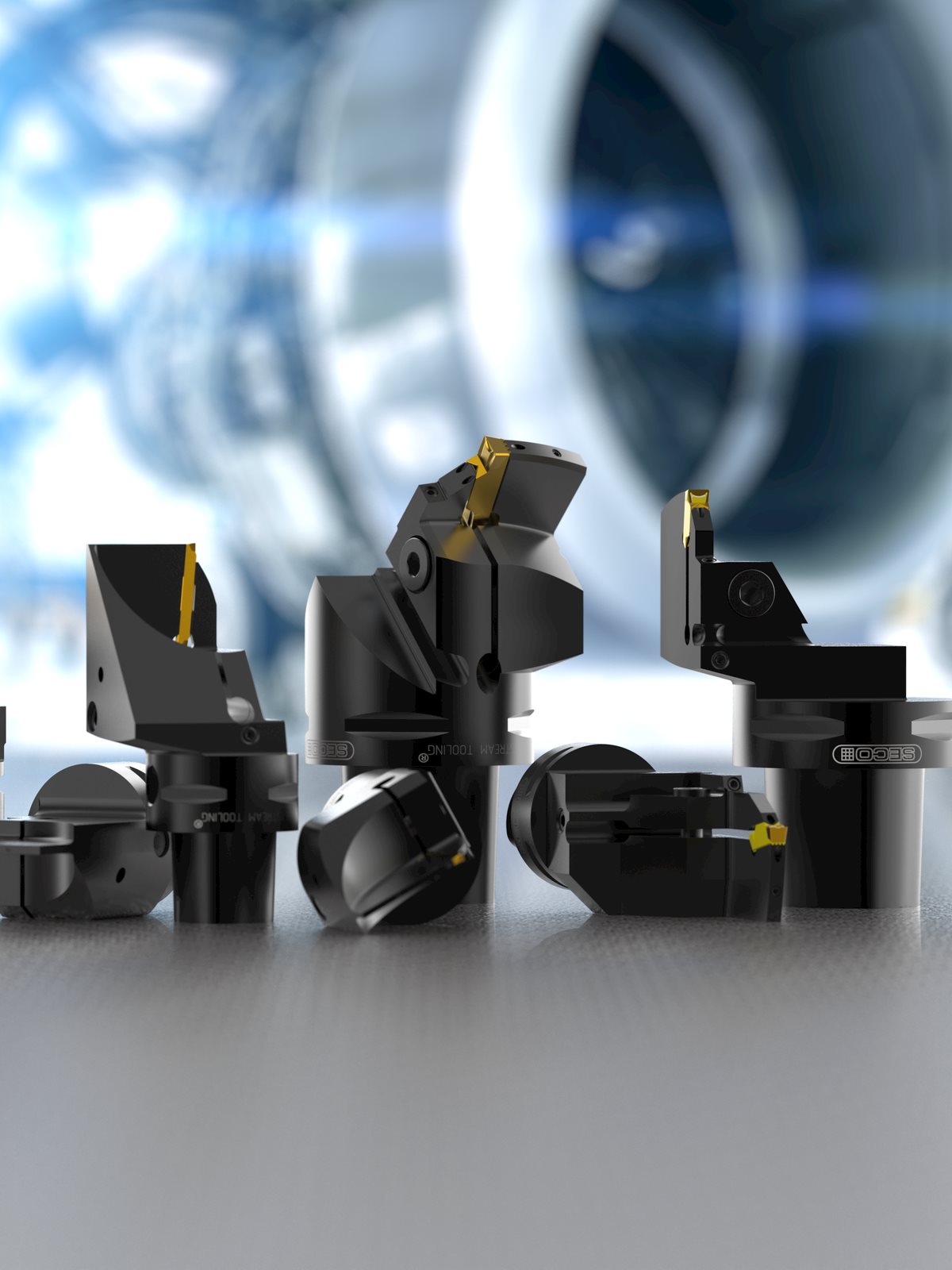

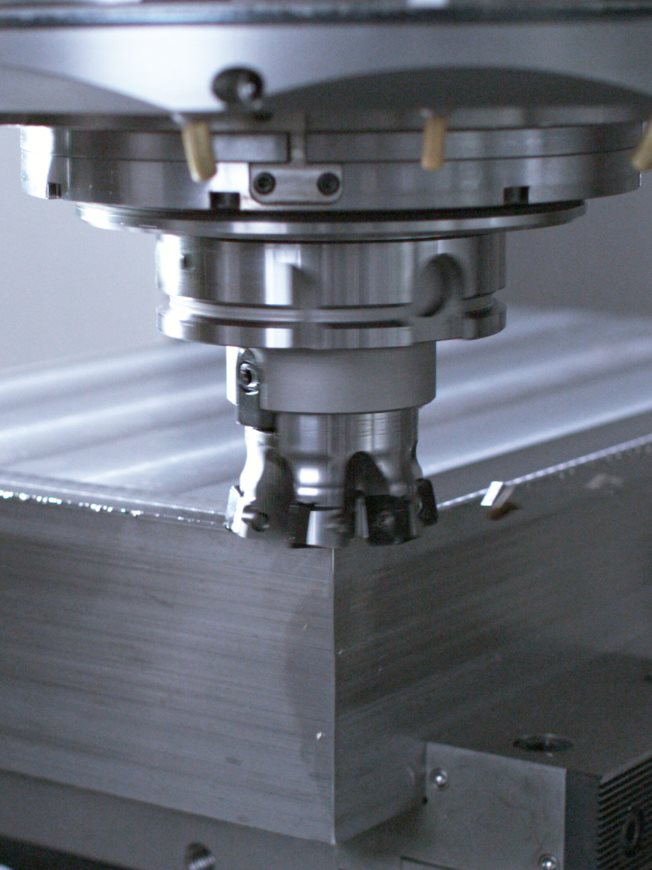

- For higher reliability and lower costs, the Seco-CaptoTM cassette-style toolholder reduces pocket wear and eliminates toolholder breakage

- For reduced stock volume and costs, Seco-CaptoTM Cassette Holders only require stocking extra cassettes

Related content

CONTACT US

PRODUCT DETAILS

Modular QC (quick-change) toolholder for small part machining

JETI ISO Toolholder range extension

Machining Navigator / Catalog Turning

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

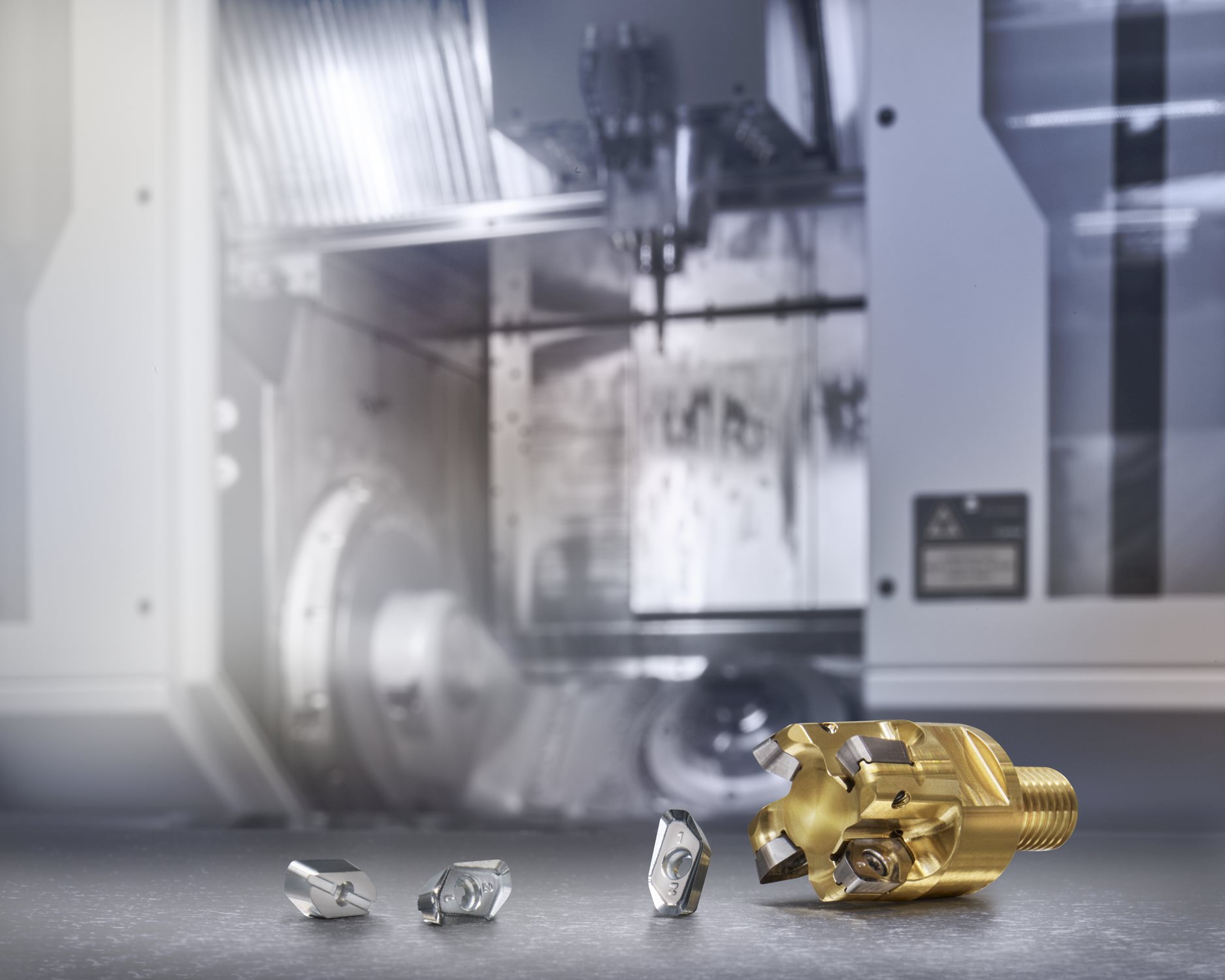

COMBIMASTER™ M20

EASYSHRINK EVO

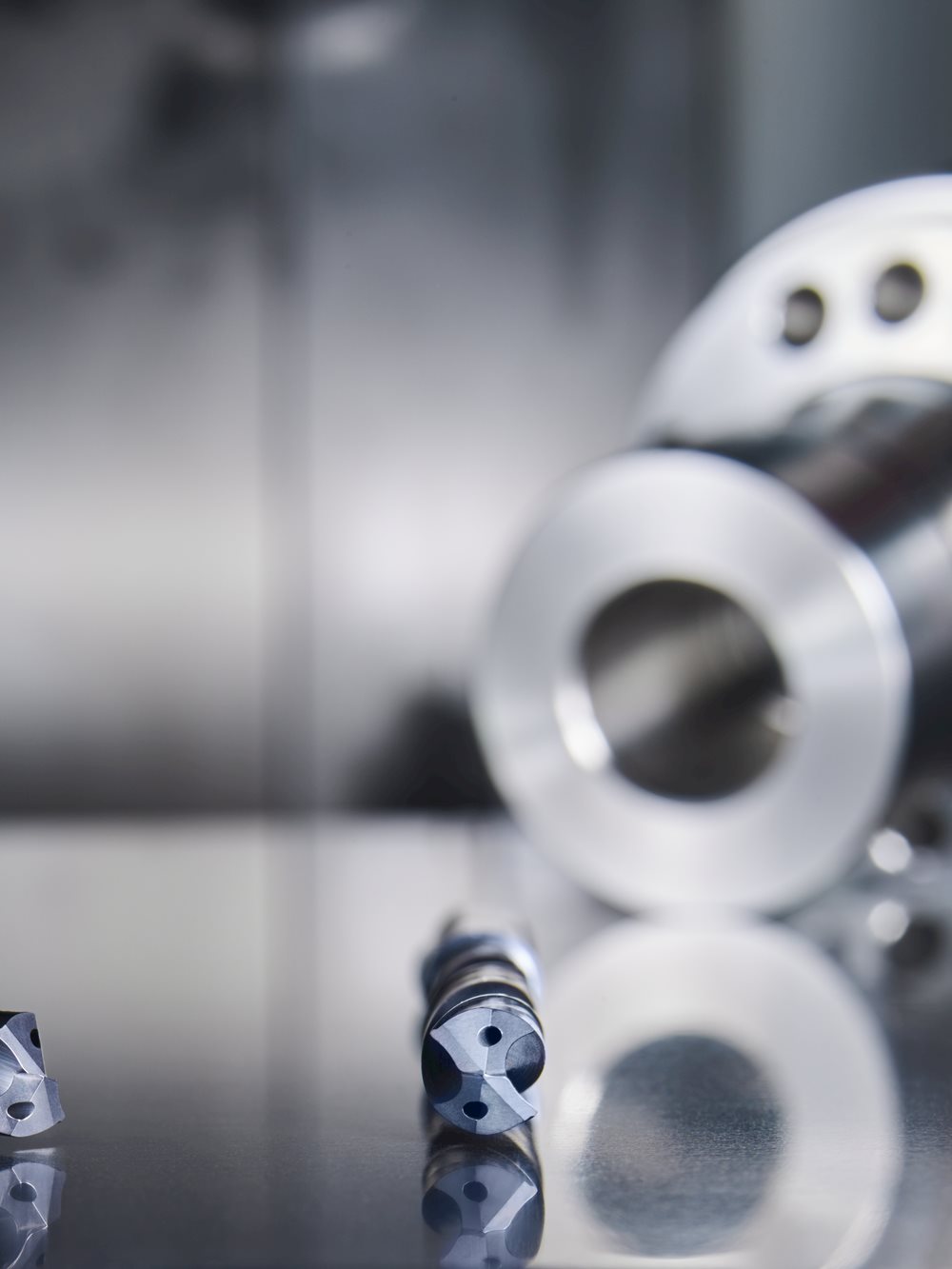

UNIVERSAL DRILLS 8XD AND 12XD

SECO ROUND 10 AND 16 COPY MILLING INSERTS

DOUBLE TURBO 16

Machining Navigator / Catalog Tooling Systems

Machining Navigator / Catalog Holemaking

Machining Navigator / Catalog Solid End Mills

Machining Navigator / Product Catalog Milling

Seco News 2020.1

Seco News Summary 2020.1

Seco Digital Tool Assembly: quick, accurate data

Optimize Multi-Task Machining Coolant And Results

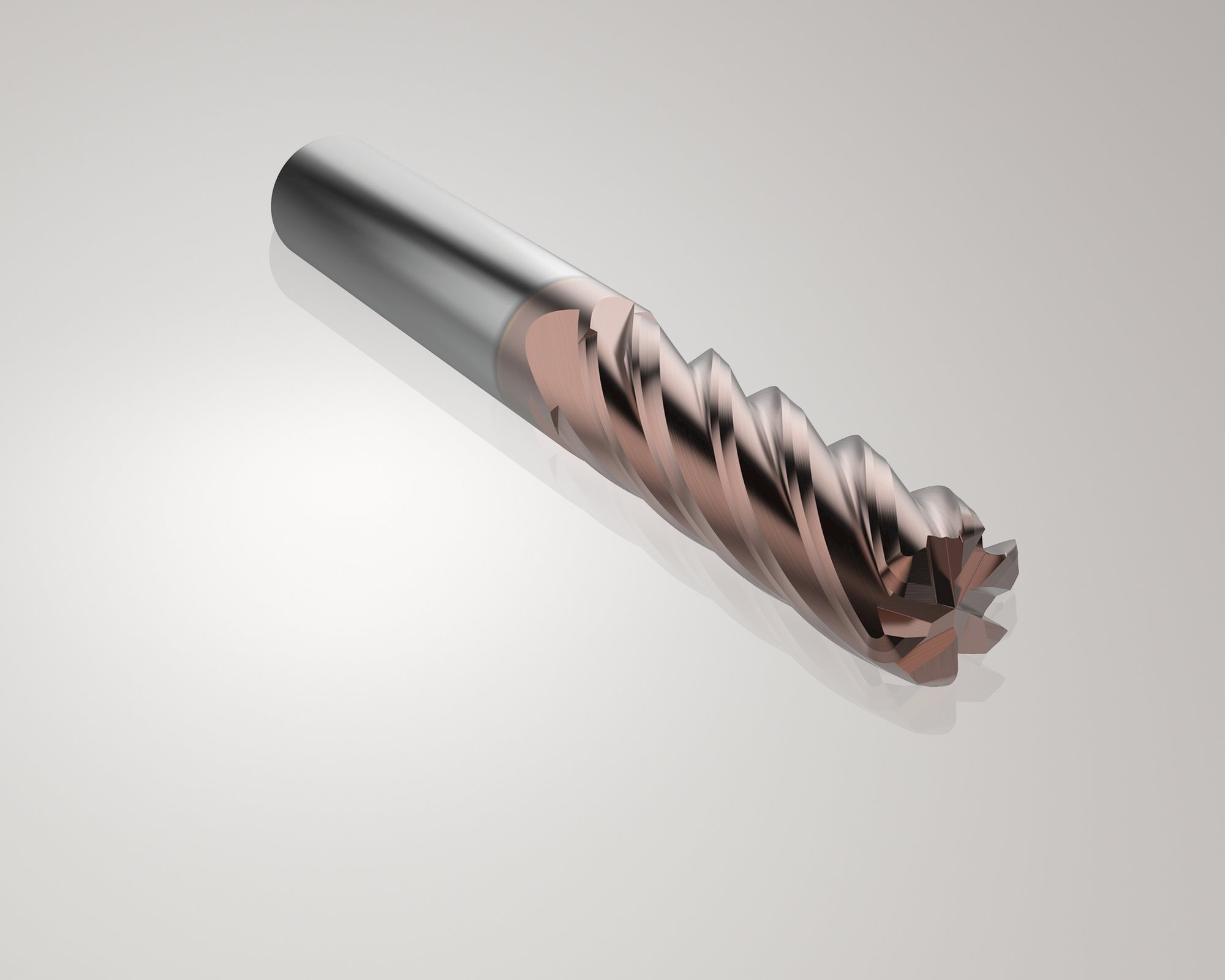

JH730 Solid End Mills addition

Seco Nanojet Reamers: reliable precision

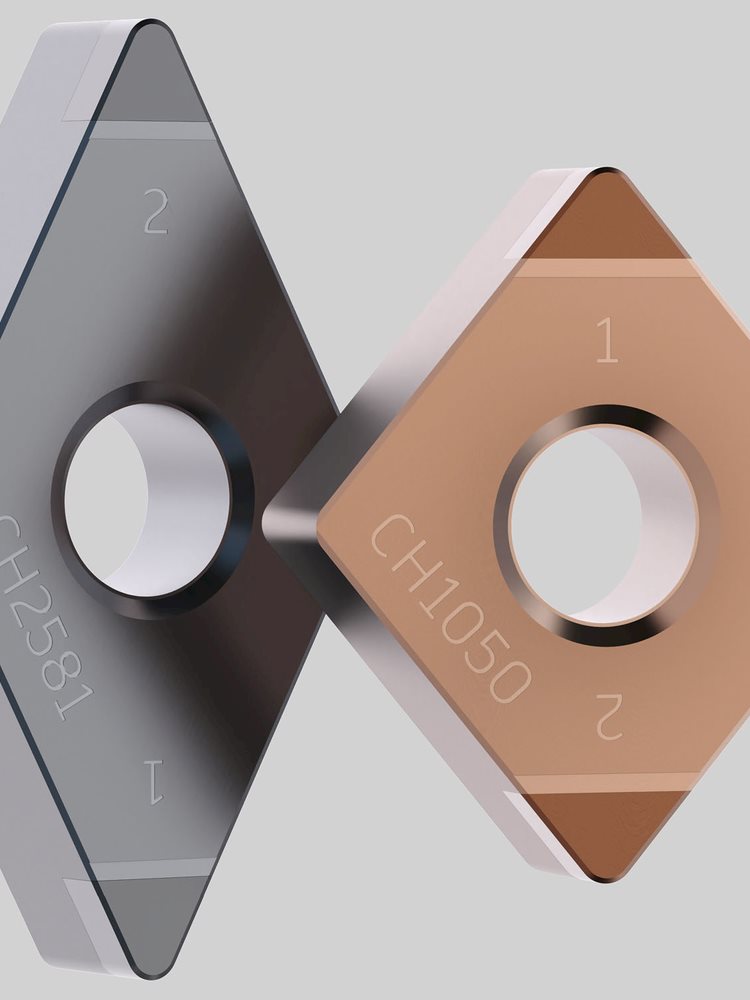

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

JS720 Solid End Mills addition

Easy setup with Seco Digital Axial Boring Heads

Square T4-12 Upgrades

Universal Drills

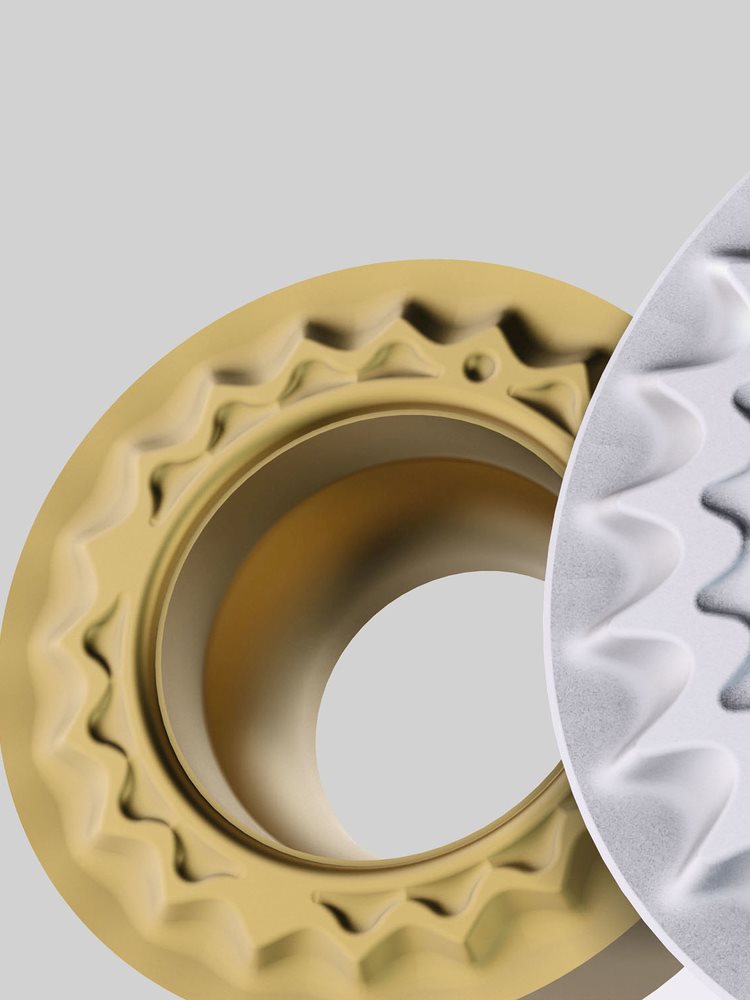

MF2 Chipbreaker on Round RCMT/RCGT Inserts

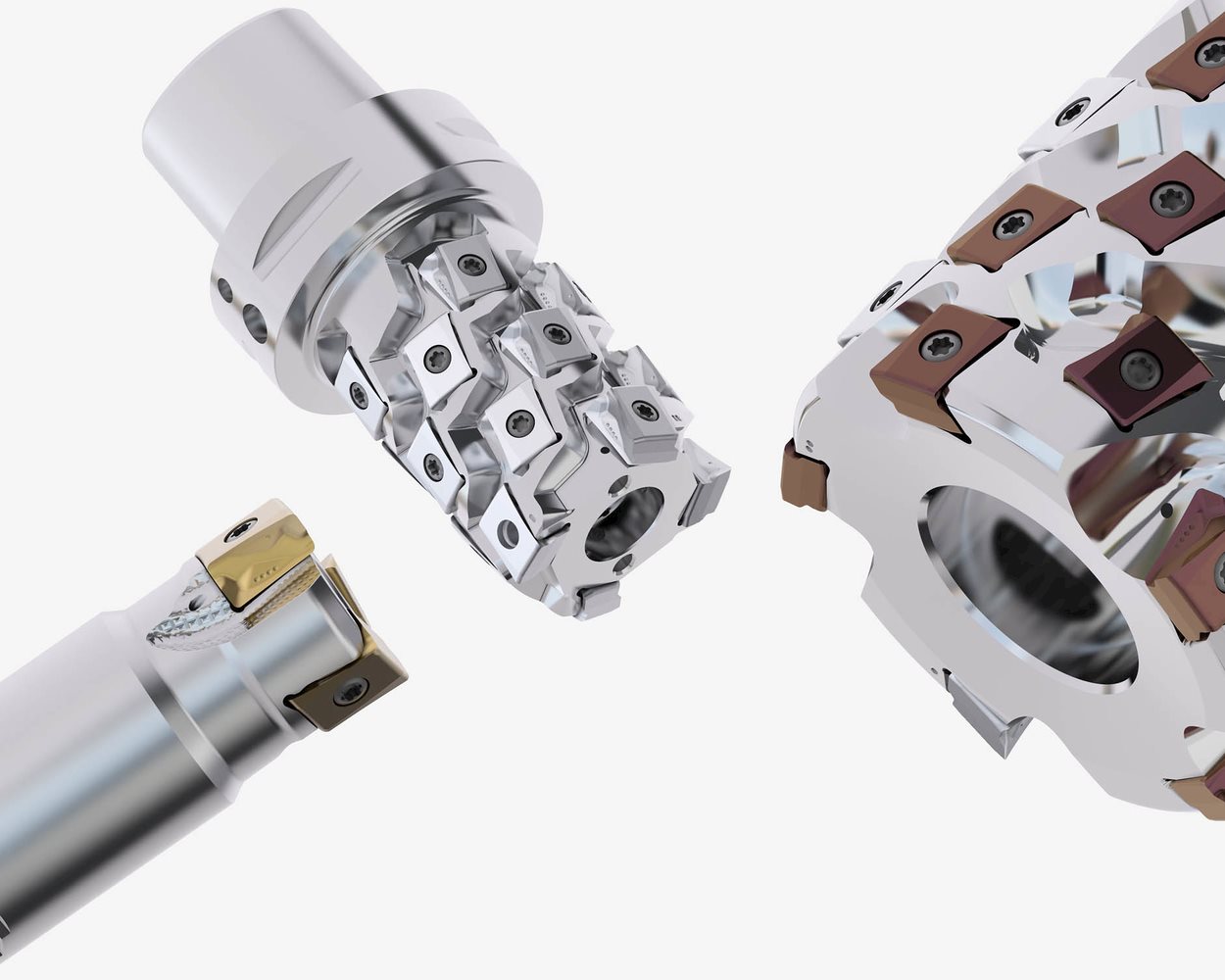

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

Precision, power, and strategy in every cut

Drill better, faster, smarter

Designed to remove more, faster

The ultimate solution for Cast Iron machining, wet or dry

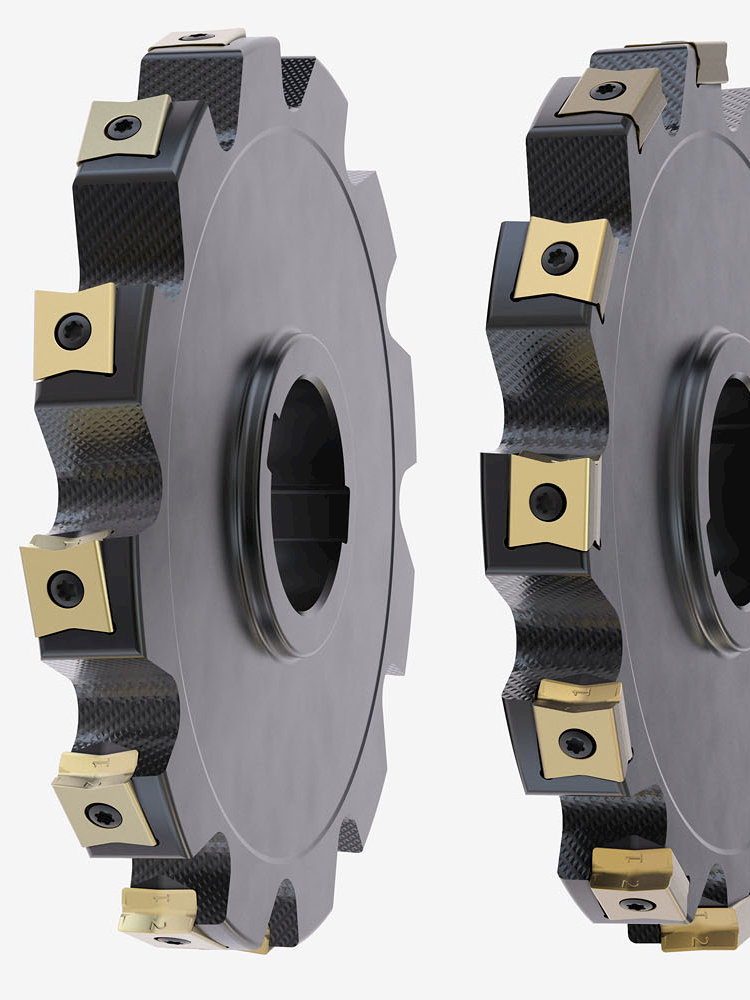

The 335.18 Disc Milling Cutter – Built for the real world

Master deep Boring with one tool

Easy to choose and easy to use

Indexable Milling system for daily machining demands

Fed up with tool changes? Speed up your machining with MP2051 grade!

Your perfect finish starts here

Seco T35 Taps: match Tooling to Materials

Seco My Design

ITI 2025: Technical days dedicated to machining in France

Seco 335.98 Disc Milling Cutter system

Seco Component Guidance

Seco Octomill™ 06: Flexible, Robust Tooling

Versatile Round 20 Inserts Increase Tool Life

DOUBLE QUATTROMILL™ 22

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

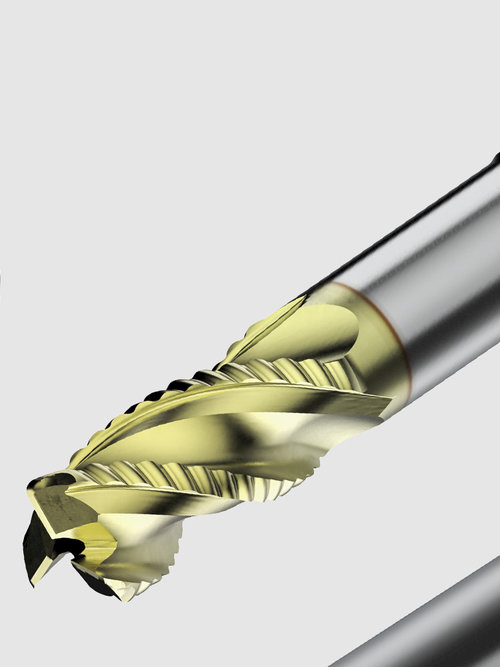

Seco Stabilizer Series: Unmatched Metal Removal

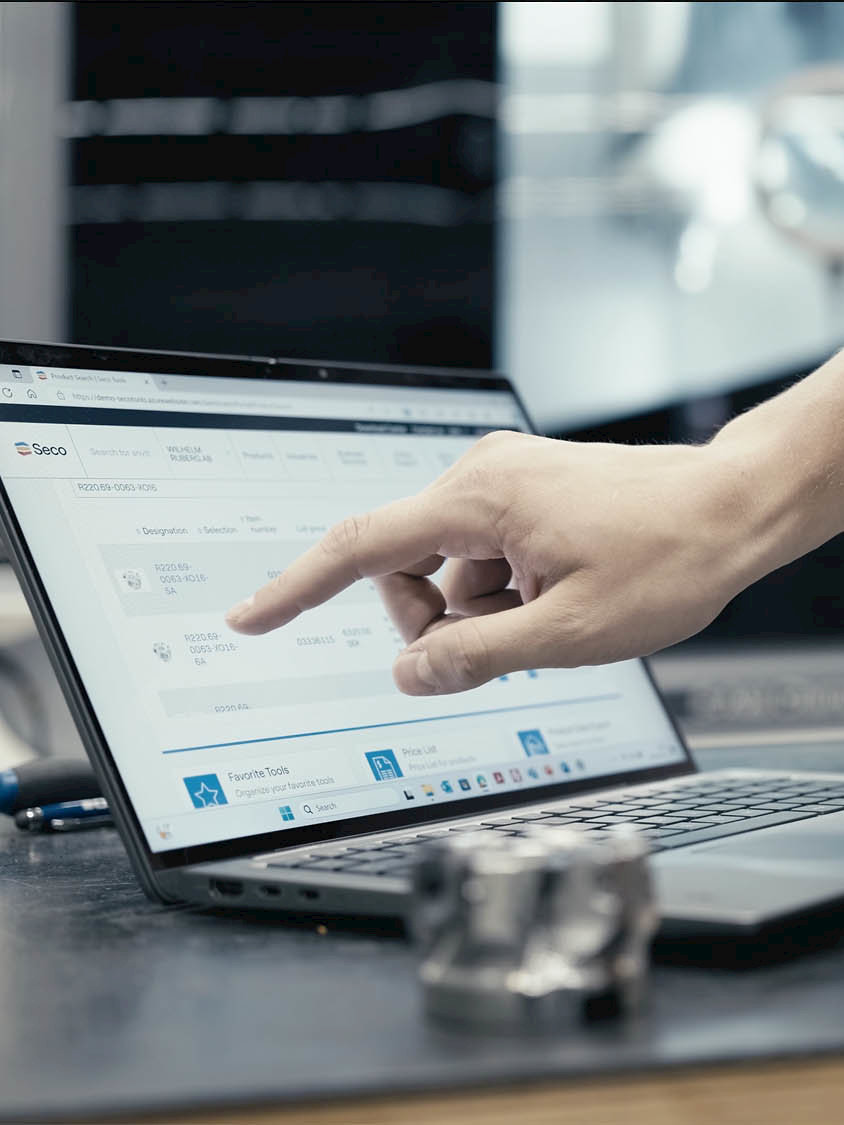

Seco Machine Library

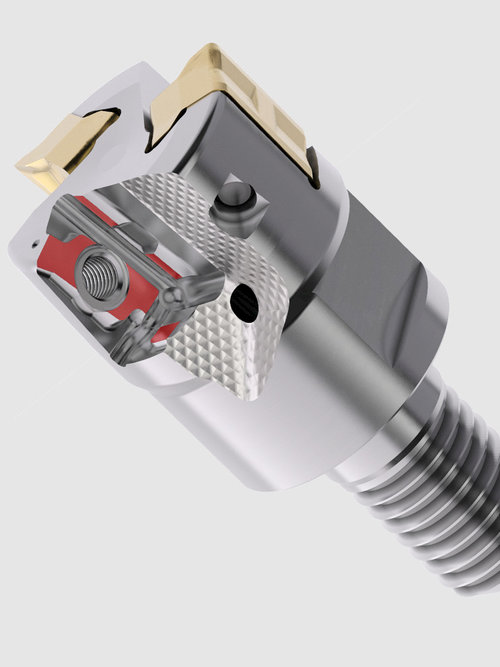

Seco X-Head Exchangeable End Mill System

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

JETI CONVERSION GROOVING AND PARTING-OFF

Seco X2 System for Small Part Machining

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Seco C-Series General Purpose End Mills

Steadyline® ø25mm (1”) series

New MP Milling Grades

JETI conversion Grooving and Parting-off Capto

JM100 MINI END MILLS

High Feed square cut size 14 insert

ISO K Threading Taps

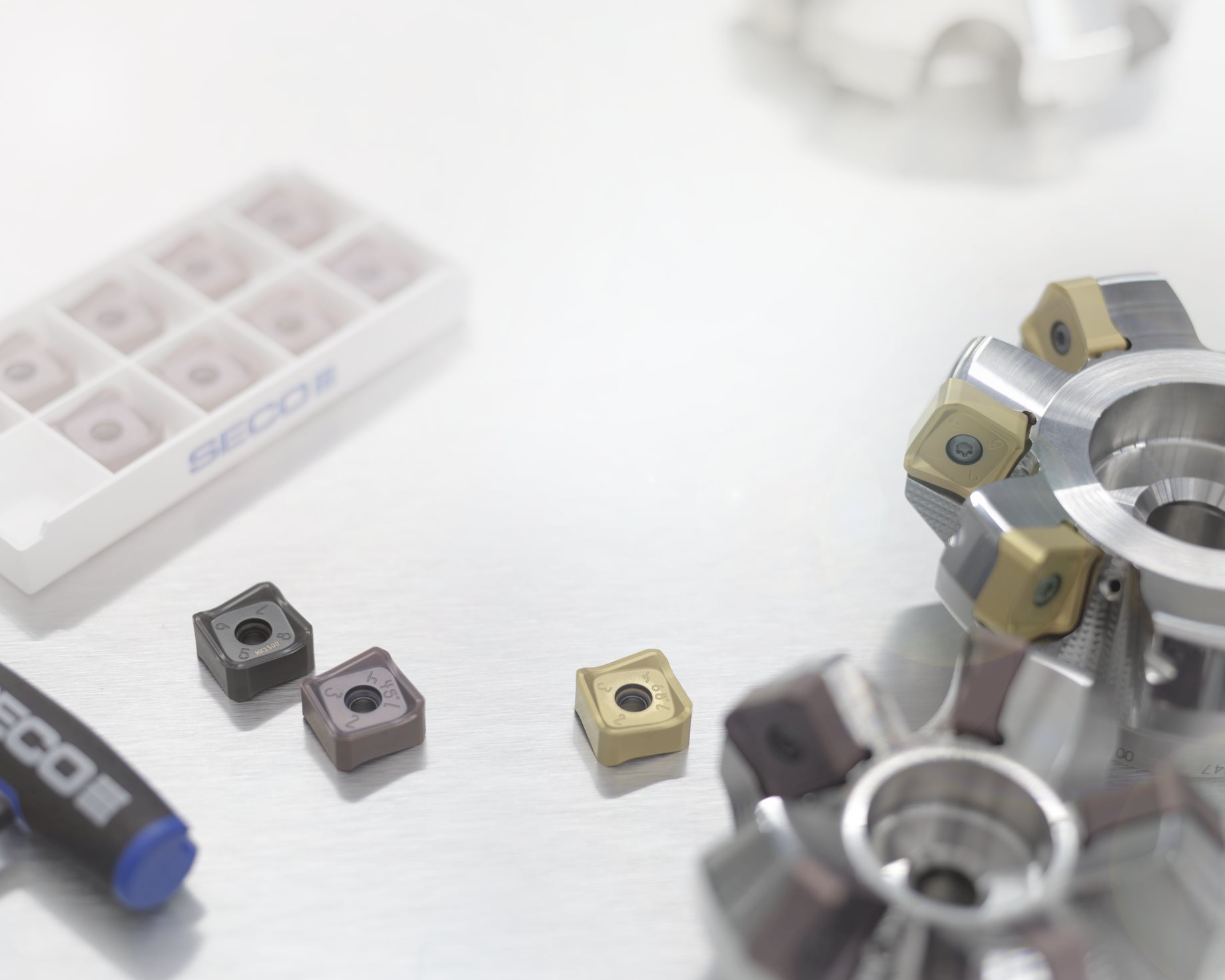

R220.88 WITH SNMU INSERTS

TTP2050

DOUBLE QUATTROMILL™ 14

DOUBLE OCTOMILL™