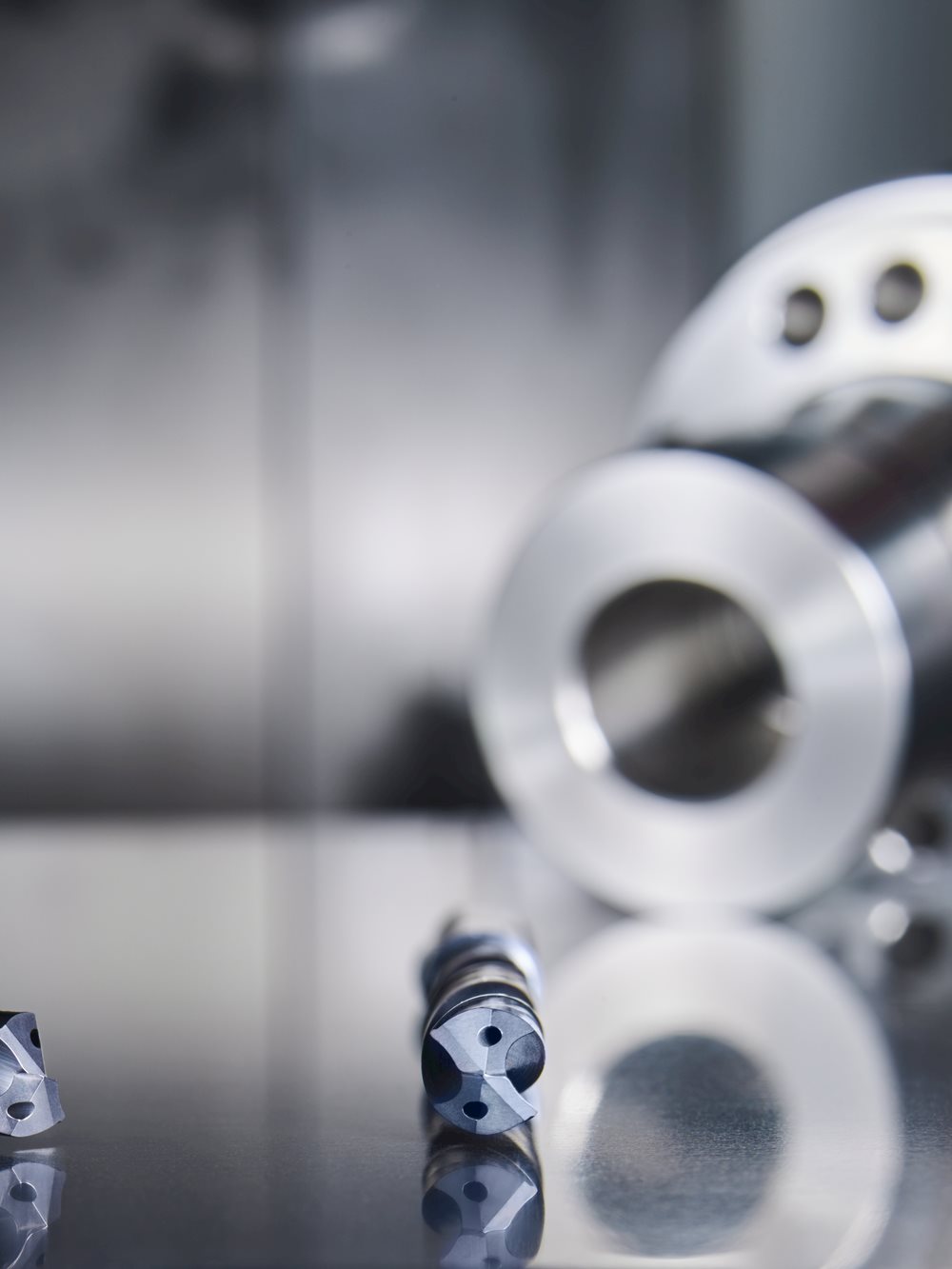

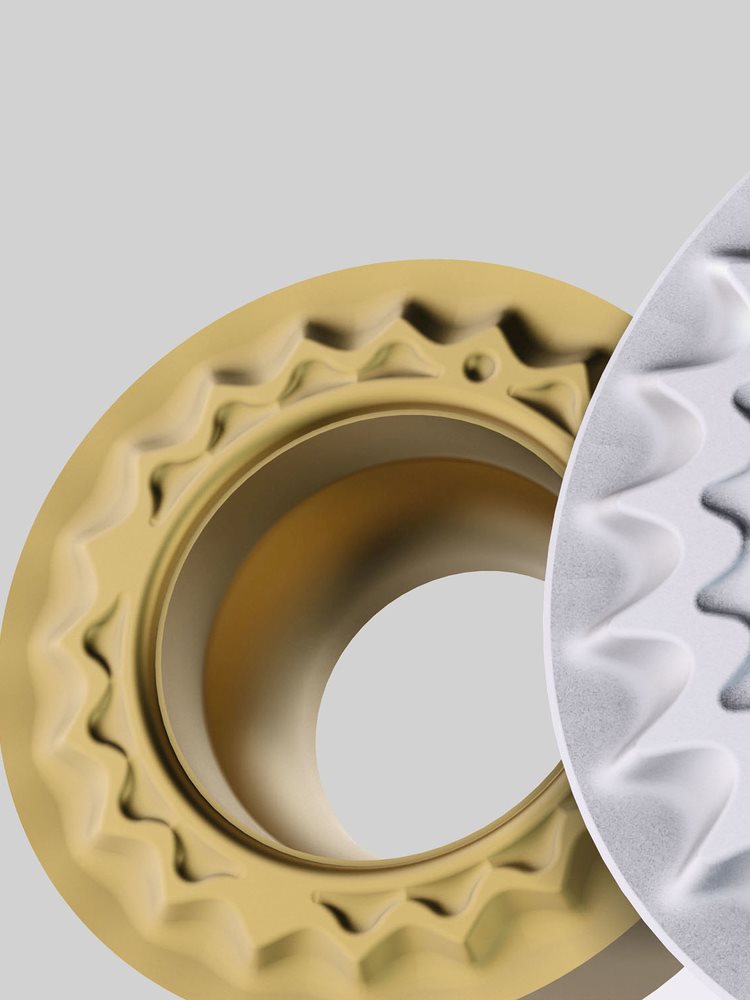

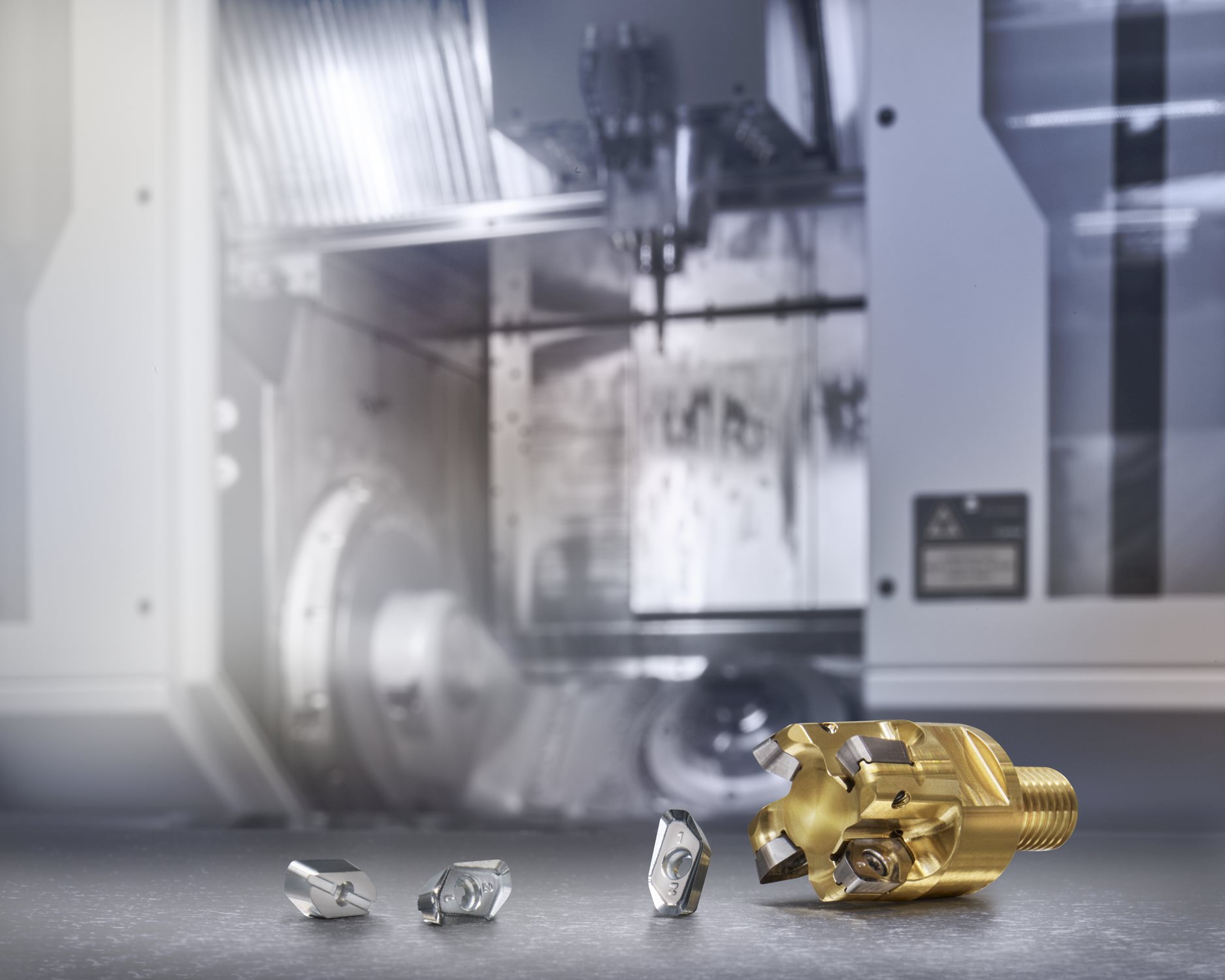

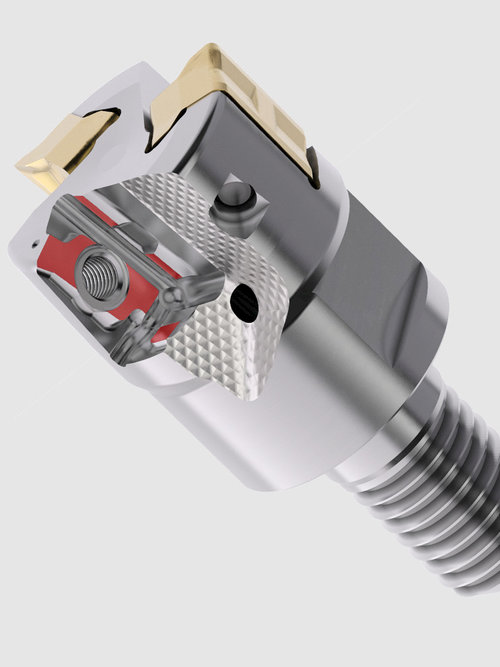

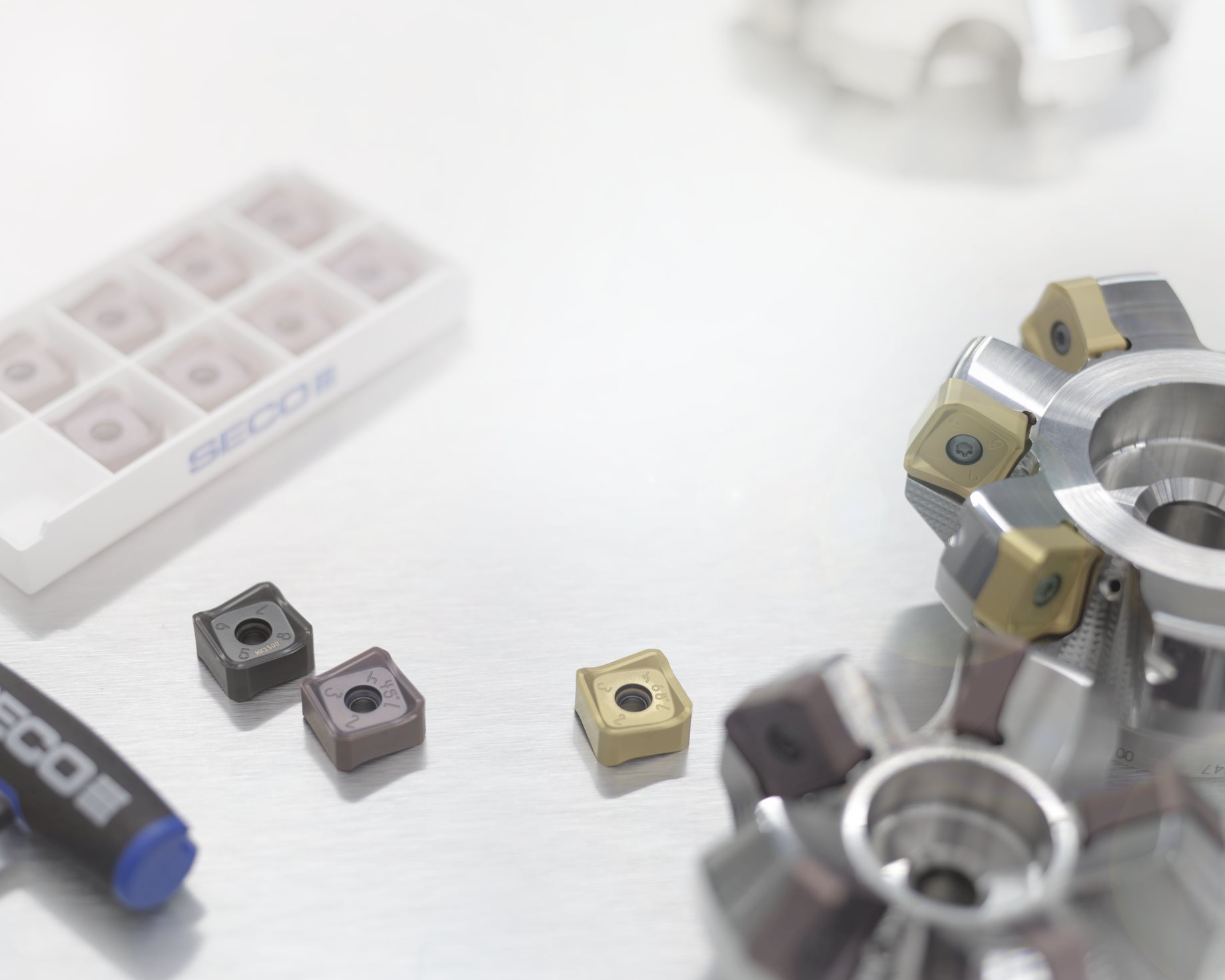

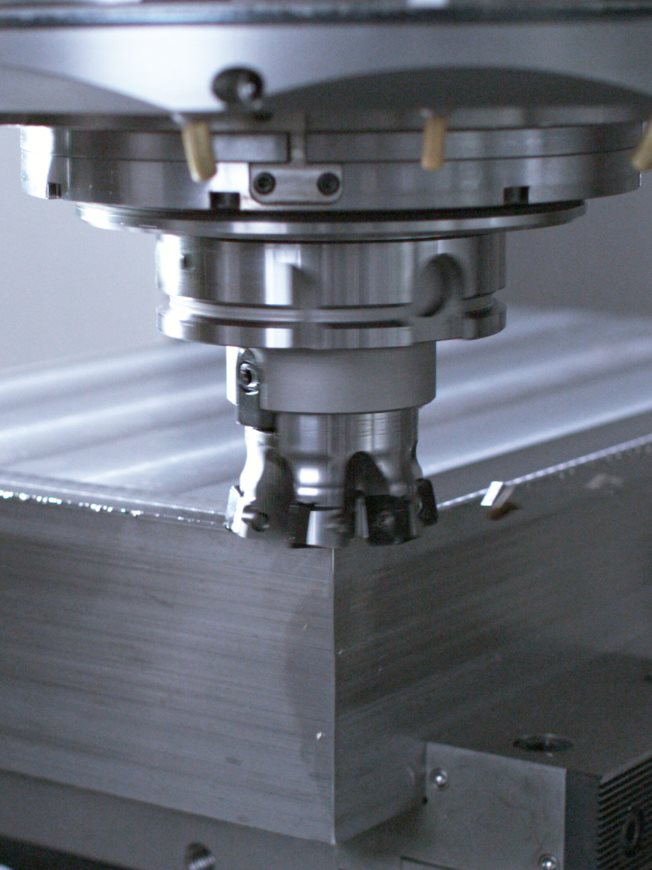

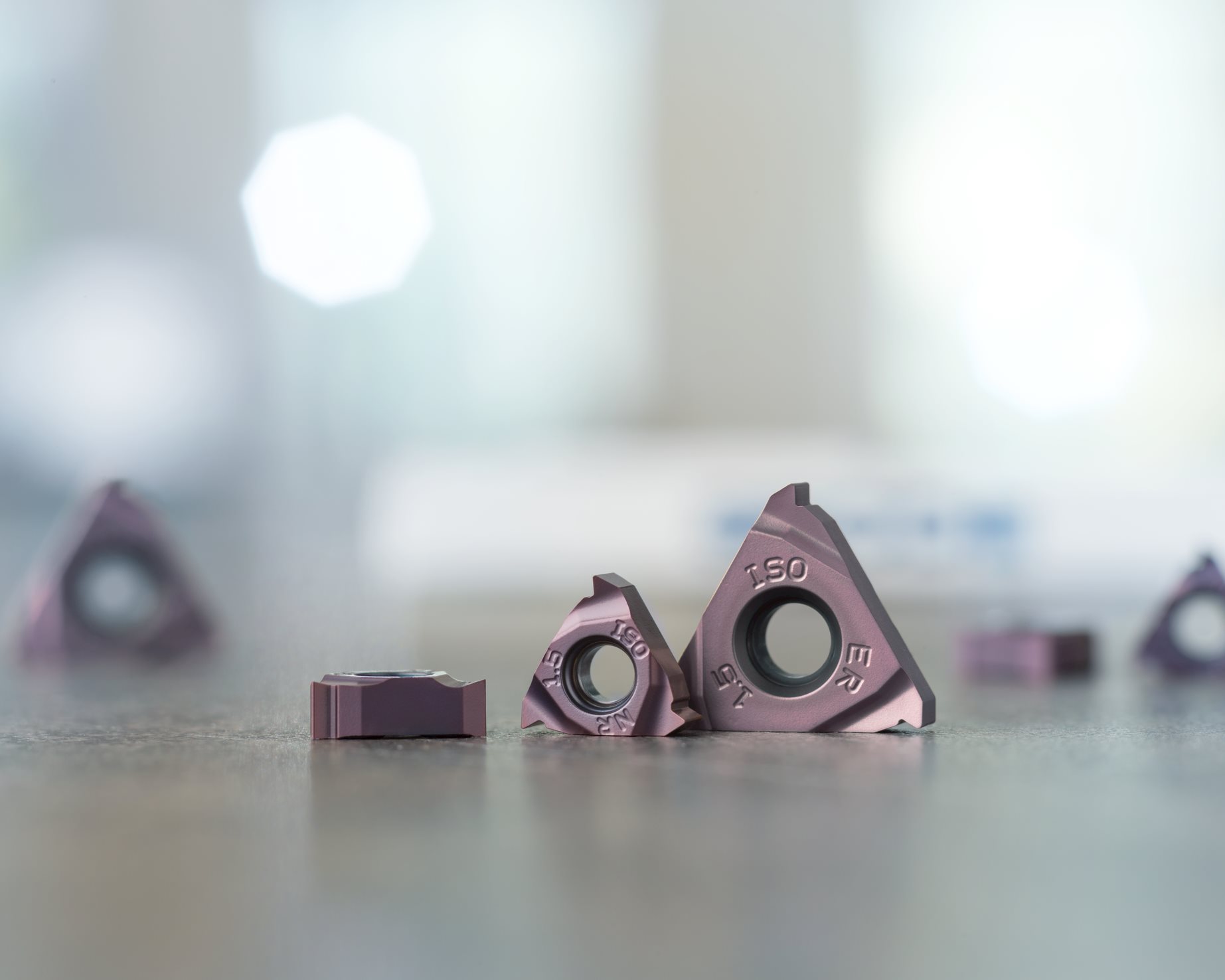

FOR LONG TOOL LIFE AND PROCESS STABILITY, KEEP ROUND INSERTS IN PLACE

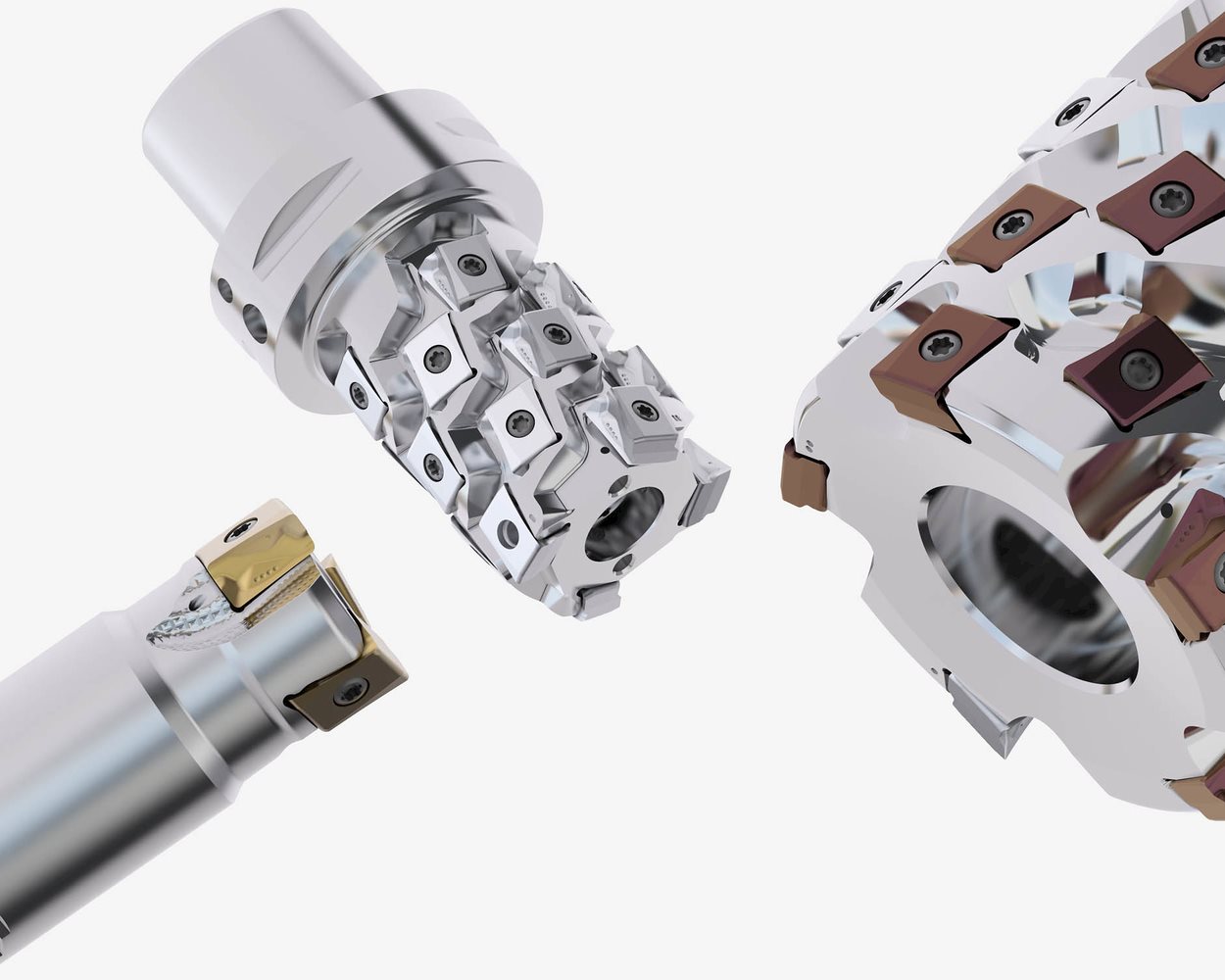

You lose tool life and process security when inserts rotate in cutter body pockets during milling operations. Keep inserts locked in place, especially in heavy or rough machining operations, with our Round 10 and 16 milling inserts.YOUR BENEFITS:

- Process security thanks to indexed inserts

- Cost effectiveness due to optimized design

- Stability due to anti-rotation feature

YOUR CHALLENGES:

- Waste of unused edges undermines your machining economy and productivity

- Process security is compromised and tool life is shortened when inserts rotate in cutter body pockets

OUR SOLUTIONS:

- Seco Round 10 and 16 milling inserts ensure fast, easy and precise indexing

- Anti-rotation feature incorporated into Seco Round 10 and 16 milling inserts

Related content

CONTACT US

PRODUCT DETAILS

Machining Navigator / Product Catalog Milling

Video: Keep Round 10 Inserts Locked In Place When Copy Milling

Video: Round Copy Milling Inserts For Longer Tool Life & Process Stability

Video: ROUND 10 INSERTS: FOR LONG TOOL LIFE AND PROCESS STABILITY

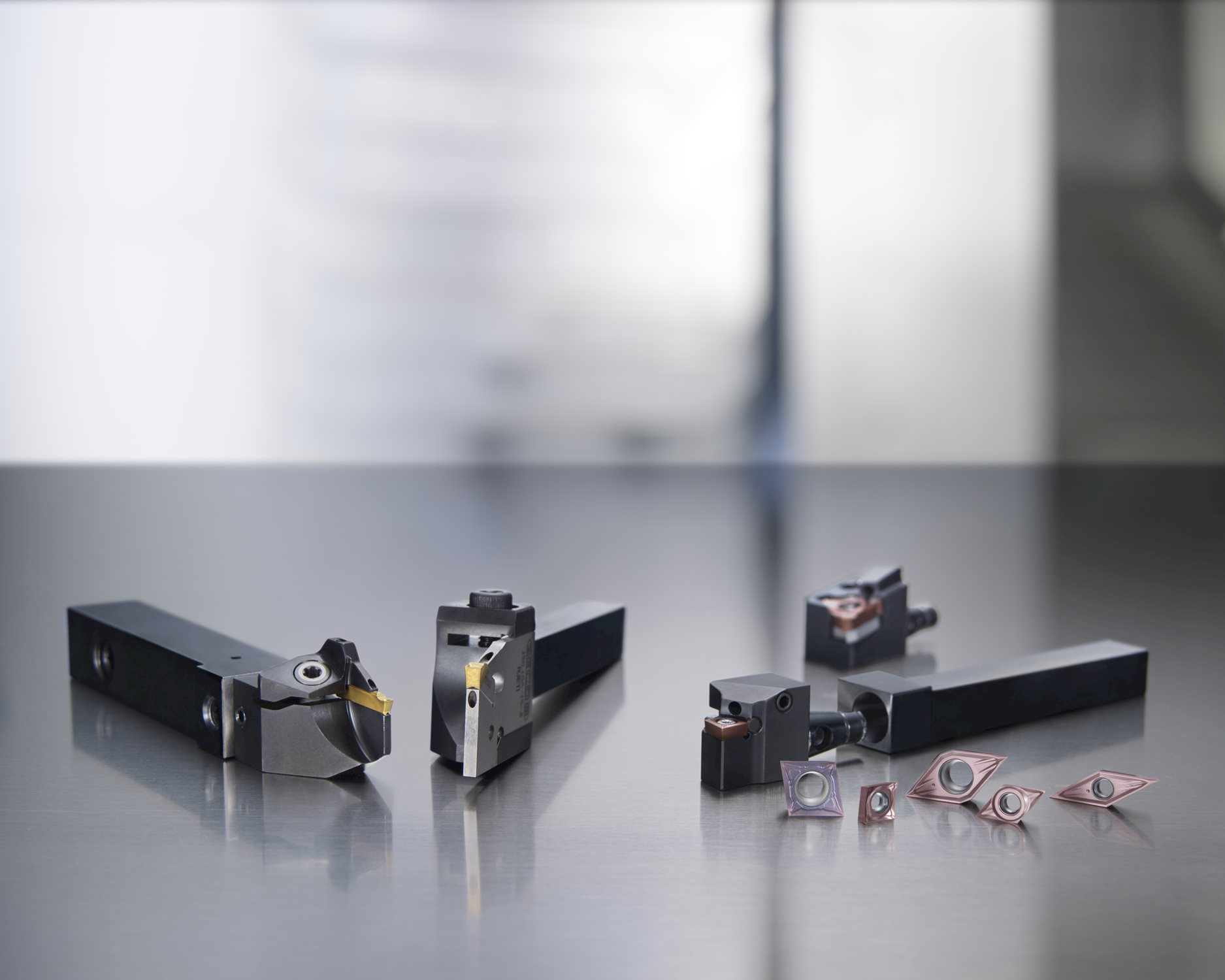

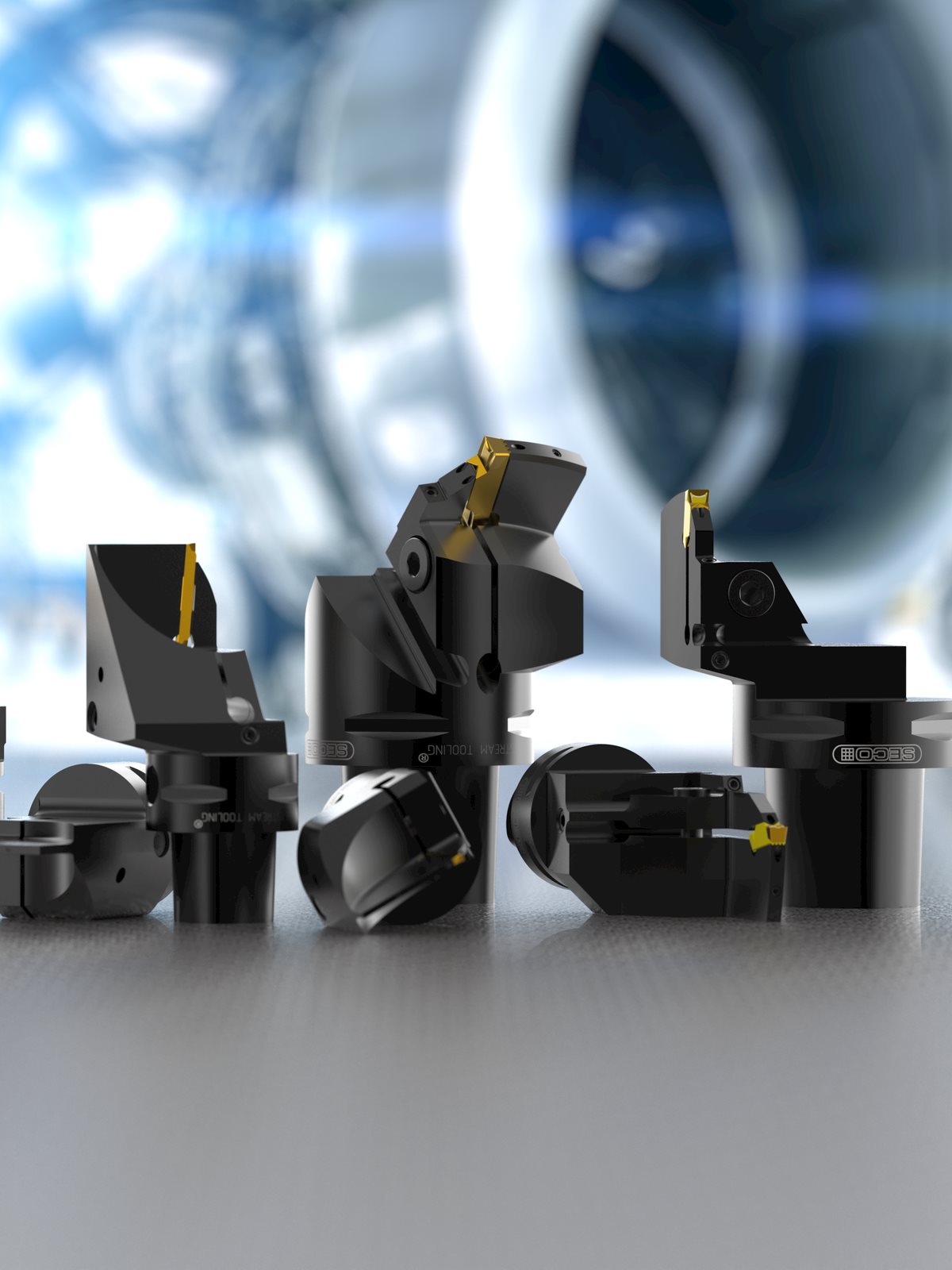

Modular QC (quick-change) toolholder for small part machining

JETI ISO Toolholder range extension

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

Seco Digital Tool Assembly: quick, accurate data

Optimize Multi-Task Machining Coolant And Results

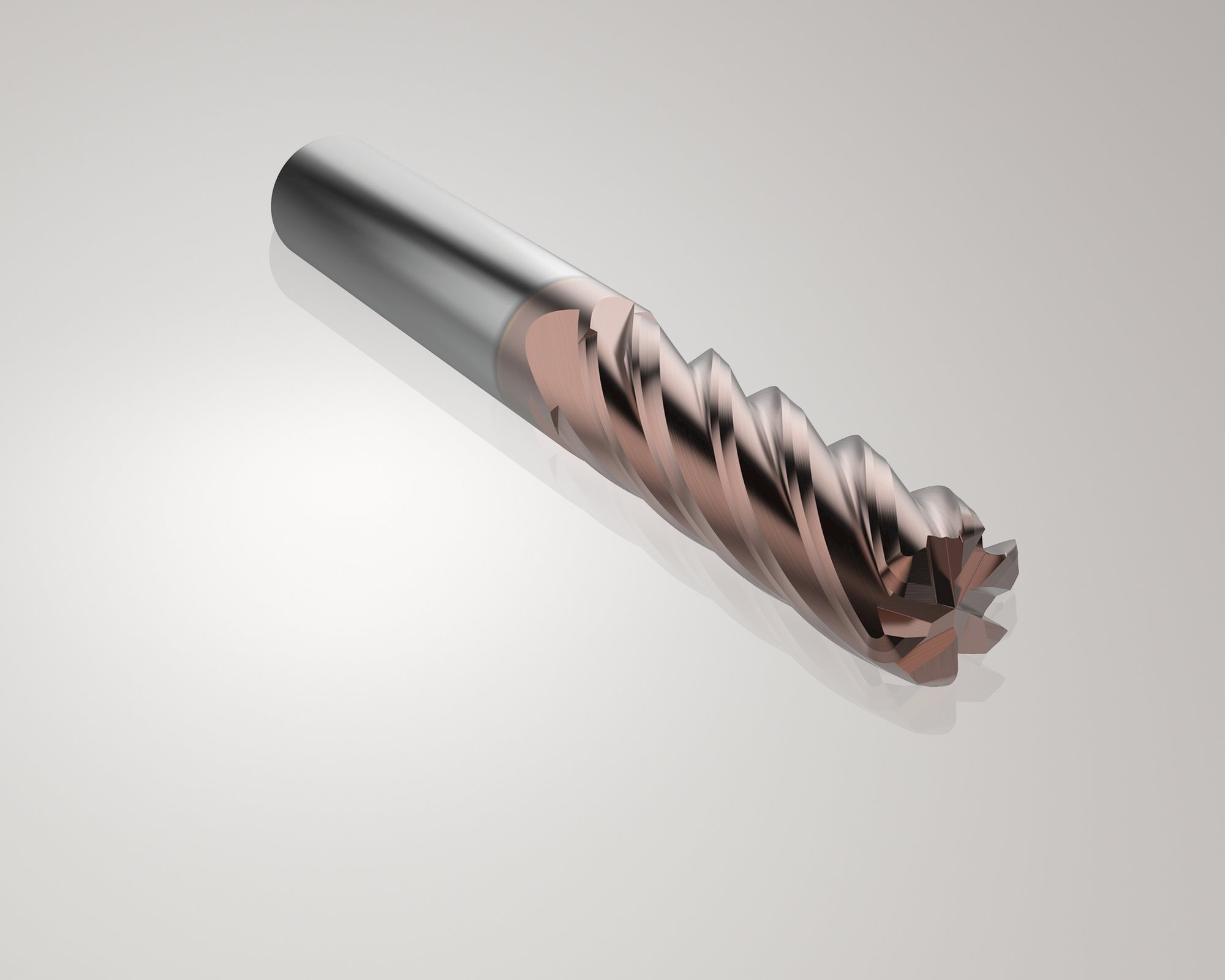

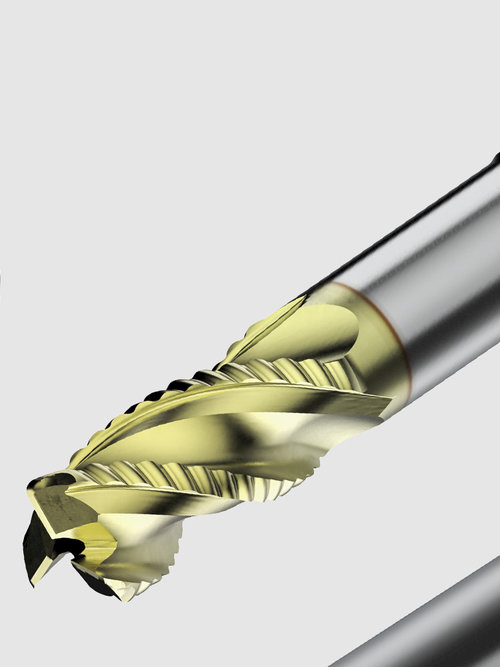

JH730 Solid End Mills addition

Seco Nanojet Reamers: reliable precision

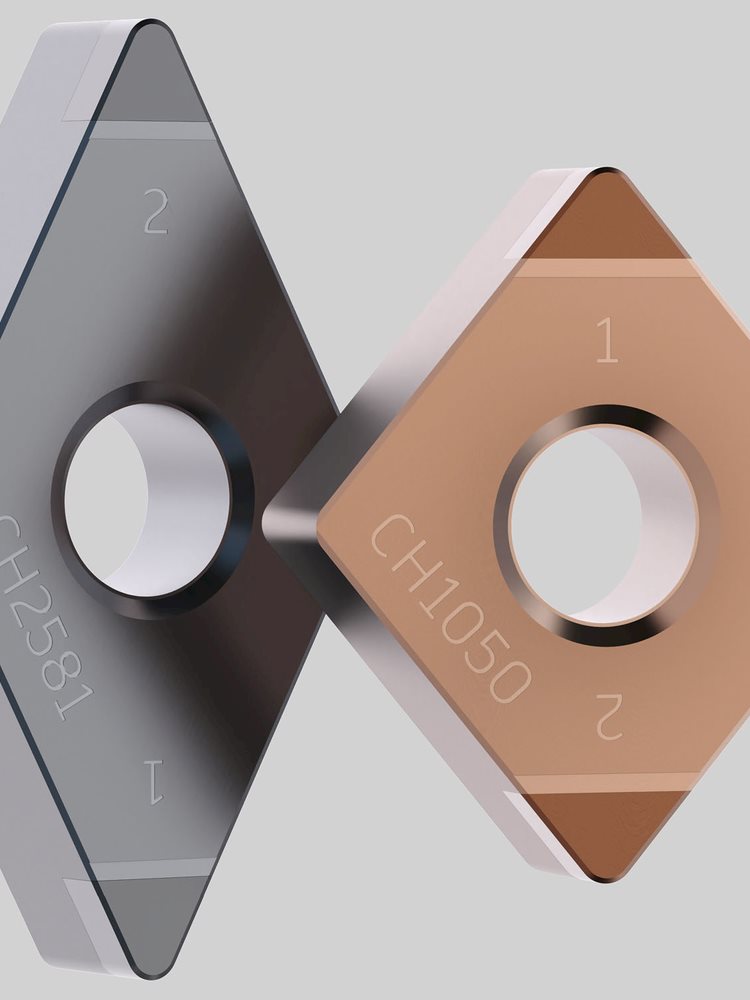

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

JS720 Solid End Mills addition

Easy setup with Seco Digital Axial Boring Heads

Square T4-12 Upgrades

Universal Drills

MF2 Chipbreaker on Round RCMT/RCGT Inserts

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

DOUBLE TURBO 16

Master deep Boring with one tool

The ultimate solution for Cast Iron machining, wet or dry

Easy to choose and easy to use

Indexable Milling system for daily machining demands

Fed up with tool changes? Speed up your machining with MP2051 grade!

Your perfect finish starts here

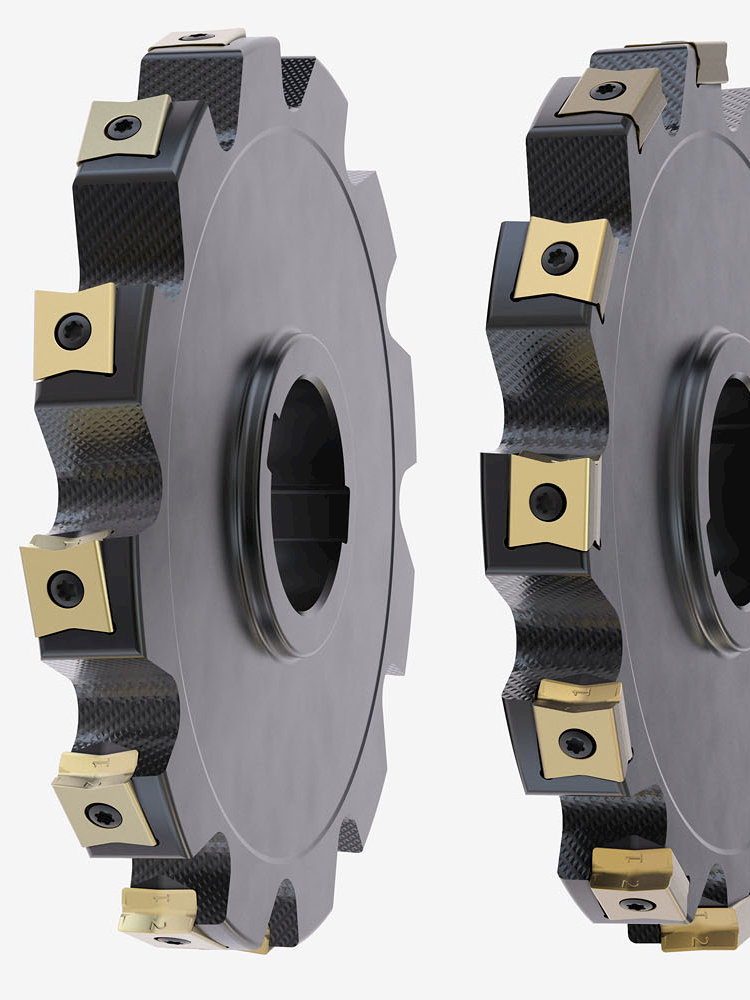

The 335.18 Disc Milling Cutter – Built for the real world

Precision, power, and strategy in every cut

Designed to remove more, faster

Seco T35 Taps: match Tooling to Materials

Seco My Design

ITI 2025: Technical days dedicated to machining in France

Seco 335.98 Disc Milling Cutter system

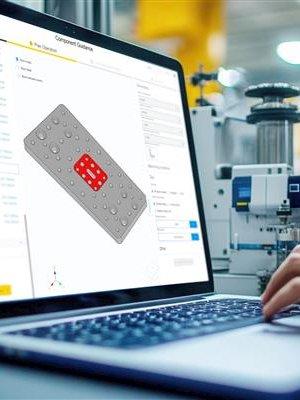

Seco Component Guidance

Seco Octomill™ 06: Flexible, Robust Tooling

Versatile Round 20 Inserts Increase Tool Life

DOUBLE QUATTROMILL™ 22

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Seco Stabilizer Series: Unmatched Metal Removal

Seco Machine Library

Seco X-Head Exchangeable End Mill System

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

JETI CONVERSION GROOVING AND PARTING-OFF

Seco X2 System for Small Part Machining

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Seco C-Series General Purpose End Mills

Steadyline® ø25mm (1”) series

Machining Navigator / Catalog Tooling Systems

Machining Navigator / Catalog Holemaking

Machining Navigator / Catalog Solid End Mills

New MP Milling Grades

Seco News 2020.1

JETI conversion Grooving and Parting-off Capto

JM100 MINI END MILLS

High Feed square cut size 14 insert

ISO K Threading Taps

Seco News Summary 2020.1

R220.88 WITH SNMU INSERTS

TTP2050

DOUBLE QUATTROMILL™ 14

DOUBLE OCTOMILL™